Isondo Lokugaya Idayimane Lethusi lengilazi

Izici

Amasondo okugaya idayimane lethusi aklanyelwe ngokukhethekile ukugaya nokubumba izinto zengilazi. Ezinye zezici ezibalulekile zala masondo zihlanganisa:

1. I-abrasive yedayimane: Isondo lokugaya lihlanganiswe nezinhlayiya zedayimane, elihlinzeka ngobulukhuni obuphezulu nokuqina ukuze kugaywe kahle ingilazi.

2. Ibhondi yethusi: Ibhondi yethusi ihlinzeka ngokukhipha ukushisa okuhle kakhulu ngesikhathi sokugaya, inciphisa ingozi yokuphuka kwengilazi ngenxa yokushisa ngokweqile.

3. Ukugaya okubushelelezi: Ama-abrasive edayimane ahlanganiswe nama-ejenti e-bronze bonding avumela ukugaya okubushelelezi, okunembayo, okuholela ekuqedeni kwekhwalithi ephezulu endaweni yengilazi.

4. Impilo ende yesevisi: Amasondo okugaya idayimane lethusi aziwa ngokusebenza kwawo isikhathi eside, okuwenza abe yinketho engabizi kakhulu yezicelo zokugaya ingilazi.

5. Ukuhambisana: Lawa masondo afanele izinhlobo ezahlukene zengilazi, kuhlanganise nengilazi yezakhiwo, ingilazi yezimoto kanye nengilazi yokuhlobisa.

6. Ukunemba: Amasondo okugaya aklanyelwe ukunikeza ukubunjwa okunembile nokugaya, okuwenza alungele izinhlelo zokusebenza lapho ukunemba kubaluleke kakhulu, njengokukhiqizwa kwezingxenye zengilazi.

7. Nciphisa ukuchopha: Amasondo e-bronze edayimane aklanyelwe ukusiza ukunciphisa ukuqhekeka nokuqhekeka kwengilazi, okuholela ekuhlanzekeni, unqenqema olupholisheke kakhulu.

8. Ukuguquguquka: Lawa masondo okugaya angasetshenziselwa kokubili ukugaya okungalungile nokupholishwa kahle, okuwenza abe ithuluzi elisebenza ngezindlela eziningi ekwenzeni ingilazi nezinqubo zokwenziwa.

PRODUCT umbukiso

Izici

1. Ukusebenza kahle okuphezulu: Amasondo okugaya idayimane lethusi aziwa ngokusebenza kwawo okuphezulu kokugaya, okungasusa izinto zokwakha futhi amise izindawo zengilazi ngokushesha.

2. Impilo ende yesevisi: Uma kuqhathaniswa namasondo okugaya endabuko, lawa masondo okugaya anempilo ende yesevisi, enciphisa imvamisa yokushintshwa kwesondo lokugaya, okungasindisa izindleko ngokuhamba kwesikhathi.

3. Ukunemba: Ukusebenzisa ama-abrasive edayimane ahlanganiswe ne-bronze bonding kuvumela ukugaya okunembayo, okuholela endaweni yengilazi ebushelelezi, epholishiwe enokuqhekeka okuncane noma ukuqhekeka okuncane.

4. Yehlisa ukunqwabelana kokushisa: Ibhondi yethusi esondweni lokugaya ingasusa ngokuphumelelayo ukushisa futhi inciphise ingozi yokulimala okushisayo engilazini ngesikhathi sokugaya.

5. Ukuguquguquka: Amasondo e-bronze okugaya idayimane angasetshenziswa ezintweni ezihlukahlukene zokugaya ingilazi, okuhlanganisa ukugaywa okuqinile, ukubunjwa, nokupholishwa okuhle, okuwenza abe yithuluzi elihlukahlukene ekucubunguleni ingilazi nokukhiqiza.

6. I-Clean Finish: Lawa masondo akhiqiza isiphetho esihlanzekile nesisezingeni eliphezulu endaweni yengilazi, okuwenza afanelekele izinhlelo zokusebenza ezidinga ukubukeka okupholishiwe nokuchwepheshile.

7. Ukuhambisana: Amasondo okugaya idayimane lethusi ahambisana nezinhlobo ezahlukene zengilazi, okuhlanganisa ingilazi yezakhiwo, ingilazi yezimoto kanye nengilazi yokuhlobisa, ehlinzeka ngokuguquguquka ukuze isetshenziswe ezimbonini ezahlukene.

8. Ukusebenza Kwezindleko: Nakuba ukutshalwa kwezimali kokuqala kwesondo lokugaya idayimane lethusi kungase kube phezulu kunesondo elivamile lokugaya, ngokuhamba kwesikhathi, impilo yalo ende yesevisi nokusebenza kahle kuyenza ibe ukukhetha okungabizi kakhulu kokusebenza kokugaya ingilazi.

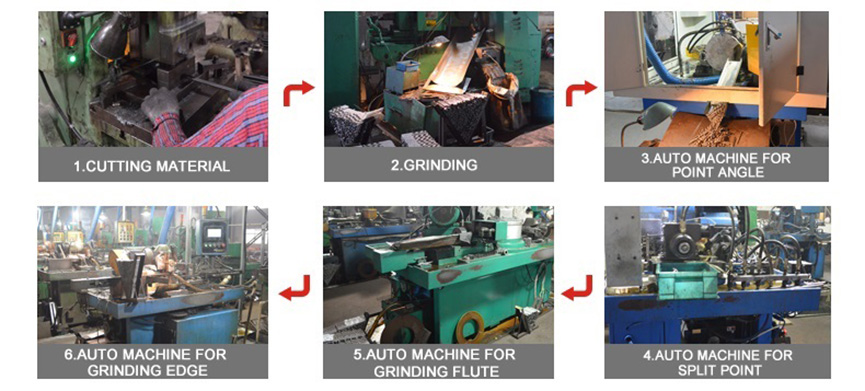

UKUHAMBA KWENKQUBO

Izinzuzo

1. Izingcezu ze-HSS twist drill zenziwe ngensimbi enesivinini esikhulu, okuwuhlobo lwensimbi yethuluzi elaziwa ngobulukhuni bayo obuhle kakhulu, ukuqina, kanye nokumelana nokushisa. Lokhu kuvumela ama-drill bits ukuthi amelane namazinga okushisa aphezulu akhiqizwa ngesikhathi sokumba, kunciphisa ingcuphe yokwehluleka kwamathuluzi nokwandisa isikhathi sazo sokuphila.

2. Izingcezu ze-HSS twist drill zingasetshenziswa ukubhoboza izimbobo ezinhlobonhlobo zezinto ezibonakalayo, ezihlanganisa insimbi, ukhuni, ipulasitiki, nezinto eziyinhlanganisela. Lokhu kuguquguquka kubenza bafanele izimboni nezicelo ezahlukahlukene.

3. Izingcezu ze-HSS twist drill zinemiphetho ebukhali esika kahle kulokho okubhojwayo. Izinto zensimbi ezinesivinini esikhulu zivumela ukujikeleza kwe-drill bit ngokushesha, okuholela ekusebenzeni okuthuthukisiwe kokusika kanye nokunciphisa isikhathi sokumba.

4. I-HSS twist drill bits iklanyelwe ukuhlinzeka ngokubhola okunembile nokunembe, ukukhiqiza izimbobo ezihlanzekile nezibushelelezi. Lokhu kubaluleke kakhulu lapho umba izimbobo zezinsimbi ezithile noma izingxenye ezidinga izilinganiso ezinembile.

5. I-Wide Range of Sizes: I-DIN338 jobber ubude be-HSS twist drill bits ayatholakala ngamasayizi ahlukahlukene ukuze afake amadayamitha embobo ahlukene. Lokhu kuvumela ukuguquguquka ekusebenzeni kokumba futhi kunikeza izinketho zobukhulu bemigodi ethile kanye nezidingo.

6. Izingcezu ze-HSS twist drill ngokuvamile zithengeka kakhulu uma kuqhathaniswa nezinye izingcezu zokubhola ezikhethekile, okuzenza zibe ukukhetha okubiza izindleko ezisetshenziswayo zokumba okuvamile. Banikeza ibhalansi enhle phakathi kokusebenza kanye nentengo, okwenza kufinyeleleke kabanzi futhi ukonga.

7. Izingcezu ze-HSS twist drill zisebenziseka kalula futhi zingasetshenzwa kalula ngemishini evamile yokumba. Banomklamo we-cylindrical shank olingana nama-drill chucks ajwayelekile, oqinisekisa ukufakwa kalula nokubopha amathuluzi avikelekile.

8. Izingcezu ze-HSS twist drill zingalolwa kabusha lapho ziba buthuntu noma zigugile. Lesi sici sivumela abasebenzisi ukuthi banwebe isikhathi sempilo yama-drill bits, sibenze bangabizi kakhulu ngokuhamba kwesikhathi.