Isondo le-Electroplated Diamond Grinding Cup lokusika nokugaya

Izici

1. I-Electroplated Diamond Coating: Isondo lenkomishi yokugaya linongqimba lwezinhlayiya zedayimane ezifakwe ugesi ku-substrate yensimbi. Le nqubo ye-electroplating iqinisekisa isibopho esivikelekile phakathi kwezinhlayiya zedayimane nesondo, okuholela ekugcinweni okuhle kakhulu kwegrit nempilo yesondo ende.

2. I-High Diamond Concentration: Amasondo enkomishi yedayimane ene-electroplated anenani eliphakeme lezinhlayiya zedayimane ezishumekwe embotsheni. Lokhu kuvumela ukugaya okusebenzayo nokunolaka, okuyenza ilungele ukususa izinto ezisetshenziswayo ngokushesha nangempumelelo.

3. Ukugaya Nokupholisha Okunembayo: Indwangu yedayimane ene-electroplated esondweni lenkomishi inikeza izenzo ezinembile nezilawulwayo zokugaya nokupholisha. Lokhu kuyenza ifanelekele izinhlelo zokusebenza ezidinga ukunemba nokunemba, njengokubumba imiphetho, ama-bevel okugaya, nokushelela izindawo ezingalingani.

4. Amasondo enkomishi yokugaya idayimane ene-electroplated angasetshenziswa ezintweni ezihlukahlukene, okuhlanganisa ukhonkolo, itshe, imabula, igwadle, nezinye izindawo eziqinile. Lokhu kuguquguquka kubenza bafanelekele uhla olubanzi lwezinhlelo zokusebenza, kusukela ekulungiseni indawo ekhonkolo kuya ekucwebezeni kwe-countertop yamatshe.

5. Ngokungafani namanye amasondo enkomishi yokugaya, isondo lenkomishi yedayimane elenziwe nge-electroplated likhiqiza isiphetho esibushelelezi nesihlanzekile, okulenza lifanelekele izinhlelo zokusebenza lapho ubuhle bubalulekile. Ingakwazi ukususa imihuzuko futhi ishiye indawo epholile ngaphandle kokudala umonakalo omkhulu noma ama-gouges.

6. Ukupholisa Nokulawula Uthuli: Ukufakwa kwedayimane esondweni lenkomishi kuvumela ukunqanyulwa kokushisa okuphumelelayo, ukuvimbela isondo ekushiseni ngokweqile phakathi nezikhathi zokugaya ezinwetshiwe. Ukwengeza, i-electroplated coating isiza ukulawula uthuli, ukunciphisa inani lemfucumfucu kanye nezinhlayiya ezikhiqizwa ngesikhathi sokugaya.

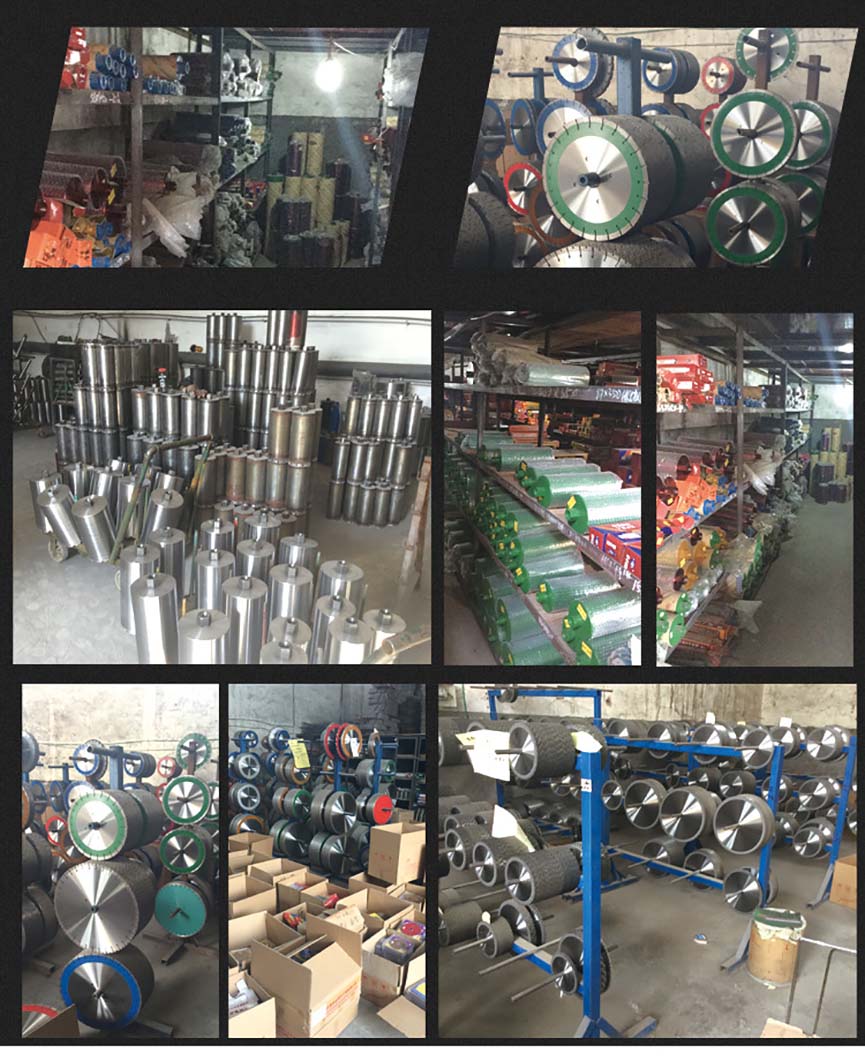

workshop

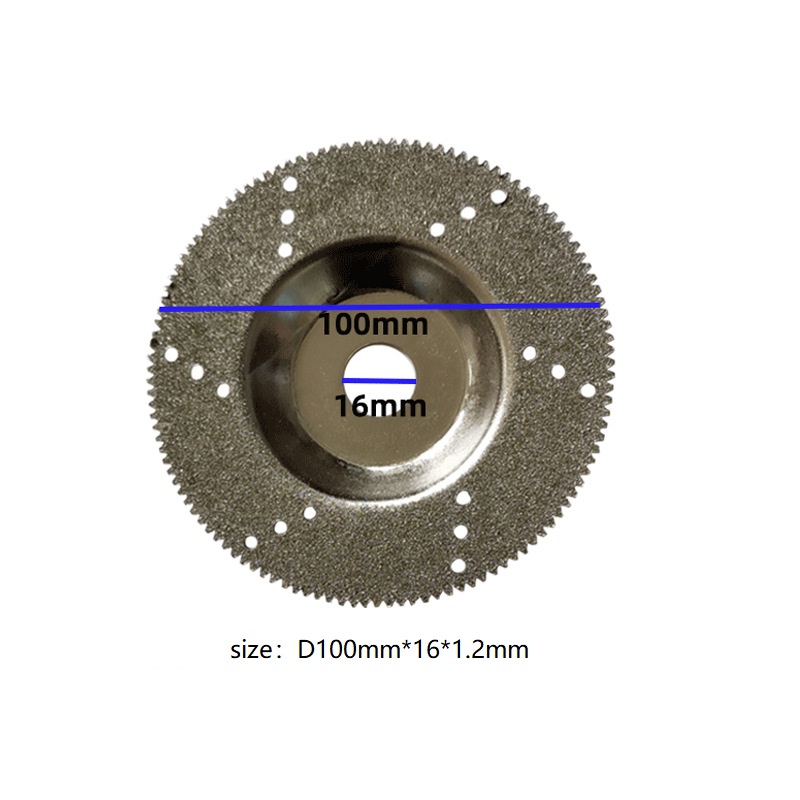

iphasela