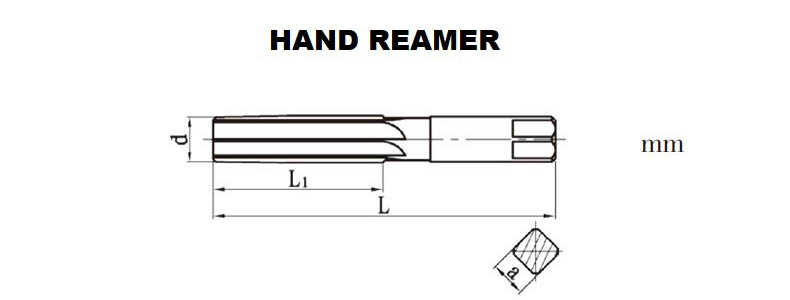

I-HSS Hand Reamer eneFlute eqondile

I-HSS Hand Reamer DIN206 BS328/ISO236

| D | L | l | D | L | l |

| 5 | 87 | 44 | 23 | 215 | 107 |

| 5.5 | 93 | 47 | 24 | 231 | 115 |

| 6 | 93 | 47 | 25 | 231 | 1165 |

| 7 | 107 | 54 | 26 | 231 | 115 |

| 8 | 115 | 58 | 27 | 247 | 124 |

| 9 | 124 | 62 | 28 | 247 | 124 |

| 10 | 133 | 66 | 30 | 247 | 124 |

| 11 | 142 | 71 | 32 | 265 | 138 |

| 12 | 152 | 76 | 34 | 284 | 142 |

| 13 | 152 | 76 | 35 | 284 | 142 |

| 14 | 163 | 81 | 36 | 284 | 142 |

| 15 | 163 | 81 | 38 | 305 | 152 |

| 16 | 175 | 87 | 40 | 305 | 152 |

| 17 | 175 | 87 | 42 | 305 | 152 |

| 18 | 188 | 93 | 44 | 326 | 163 |

| 19 | 188 | 93 | 45 | 326 | 163 |

| 20 | 201 | 100 | 46 | 326 | 163 |

| 21 | 201 | 100 | 48 | 347 | 174 |

| 22 | 215 | 107 | 50 | 347 | 174 |

Izici

1. Ukwakhiwa Kwensimbi Yesivinini Esiphezulu: Izixhumi zezandla ze-HSS zenziwe ngensimbi enesivinini esikhulu, into eqinile futhi ehlala isikhathi eside engakwazi ukumelana namazinga okushisa aphezulu futhi igcine ukusebenza kwayo kokusika.

2. Idizayini Yomtshingo Eqondile: Izixhumi zezandla ze-HSS ngokuvamile zinedizayini yomtshingo eqondile, evumela ukukhishwa kwe-chip okushelelayo nokuphumelelayo. Lokhu kusiza ukuvimbela ukuvaleka kwe-chip noma ukuminyana phakathi nenqubo yokubuyisela kabusha.

3. Ukusika Okunembile: Izixhumi zezandla ze-HSS zingaphansi kokubekezelela okuqinile ukuze kuqinisekiswe ukusika okunembile nokunembayo. Zenzelwe ukudala izimbobo ezibushelelezi, ezinembile, nezigxilile, zithuthukise ikhwalithi nokulingana kwendawo yokusebenza.

4. Ukuguquguquka: Izixhumi zezandla ze-HSS zilungele ukusetshenziswa ezintweni ezihlukahlukene, kuhlanganise nezinsimbi ezihlukahlukene, amapulasitiki, nokhuni. Angasetshenziswa emisebenzini yokumba mathupha noma ngamathuluzi kagesi abanjwe ngesandla.

5. Izixhumi zezandla ze-HSS zitholakala ngebanga elibanzi losayizi, okuhlanganisa izilinganiso ezijwayelekile zemethrikhi nezilinganiso zombuso. Lokhu kuvumela ukuguquguquka lapho kukhethwa i-reamer efanelekile yesidingo sosayizi wembobo ethile.

6. Lawa ma-reamer ngokuvamile afaka i-shank eqondile engabanjwa ngokuvikelekile ku-drill chuck, i-collet, noma isibambi sethuluzi lesandla. Umklamo we-shank oqondile uqinisekisa ukuzinza phakathi nenqubo yokuvuselela kabusha.

7. Izixhumi zezandla ze-HSS zingalola kabusha, zandise ukuphila kwazo okuwusizo futhi zinciphise isidingo sokushintshwa njalo. Lokhu kubenza babe inketho engabizi kakhulu yemisebenzi ephindaphindwayo yokuphinda yenziwe kabusha.

8. Ukwakhiwa kwensimbi enesivinini esikhulu kwenza izixhumi zezandla ze-HSS zimelane nokuguga, zinwebe ukuqina kwazo nokusebenza kukonke. Ukunakekelwa okufanele kanye nokugcotshwa kungathuthukisa impilo yabo.

9. Ukusebenza Okubanjwa ngesandla: Izixhumi zezandla ze-HSS zenzelwe ngokuyinhloko ukusebenza okubanjwa ngesandla, okuvumela ukulawula nokunemba okukhulu. Zizilungele kahle izicelo ezisendaweni noma endaweni yokusebenzela lapho umshini wokubhoboza ungase ungatholakali.

UMBUKISO WOMKHIQIZO

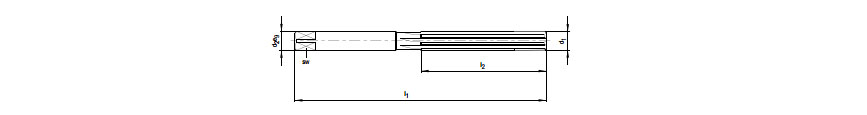

| Imininingwane d | L1 | L | a |

| 3 | 31 | 62 | 2.24 |

| 4 | 38 | 76 | 3.15 |

| 5 | 44 | 87 | 4 |

| 6 | 47 | 93 | 4.5 |

| 7 | 54 | 107 | 5.6 |

| 8 | 58 | 115 | 6.3 |

| 9 | 62 | 124 | 7.1 |

| 10 | 66 | 133 | 8 |

| 11 | 71 | 142 | 9 |

| 12 | 76 | 152 | 10 |

| 13 | |||

| 14 | 81 | 163 | 11.2 |

| 15 | |||

| 16 | 87 | 175 | 12.5 |

| 17 | |||

| 18 | 93 | 188 | 14 |

| 19 | |||

| 20 | 100 | 201 | 16 |

| 21 | 100 | 201 | 16 |

| 22 | 107 | 215 | 18 |

| 23 | |||

| 24 | 115 | 231 | 20 |

| 25 | |||

| 26 |