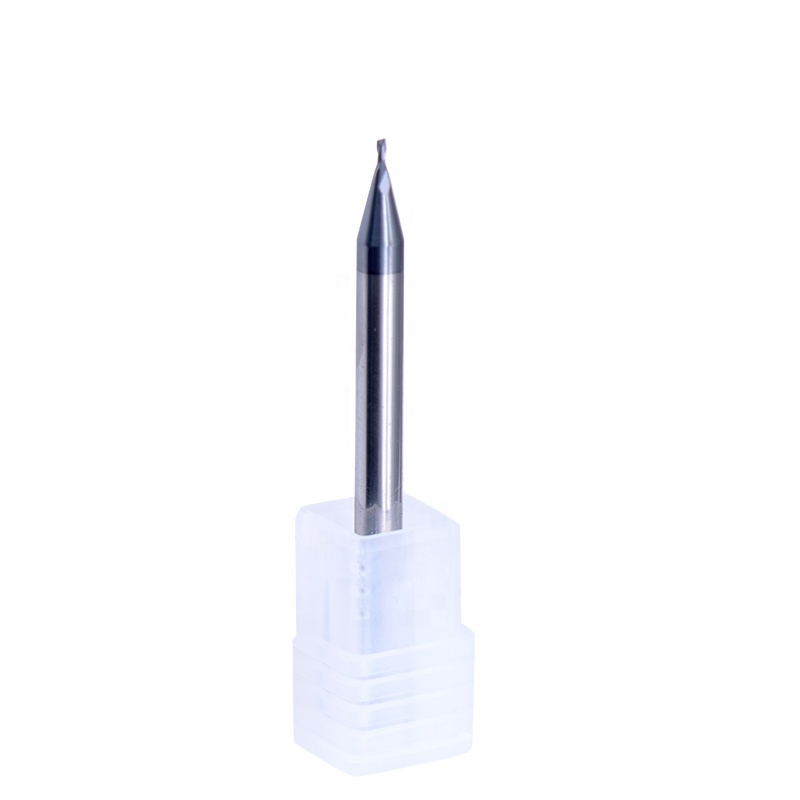

I-Micro Tungsten Carbide Square End Mill

Izici

1. Ububanzi obuncane: Izigayo ezincane ngokuvamile ziba nobubanzi obusuka ku-0.1mm ukuya ku-6mm, okuvumela ukusikeka okunembile nokuyinkimbinkimbi ezindaweni eziqinile. Lokhu kuvumela ukwenziwa kwemininingwane emihle nezici ezincane ngokunemba okuphezulu.

2. Ukuqina okuphezulu: I-Tungsten carbide yaziwa ngobulukhuni bayo obuhle kakhulu, okuqinisekisa ukuqina kwe-micro end Mill kanye nokumelana nokugqoka. Lokhu kubenza bafaneleke ukwenza izinto eziqinile njengensimbi engagqwali, izinsimbi zamathuluzi aqinile, nama-alloys omkhathi.

3. Imiphetho ebukhali yokusika: Izigayo zokugcina ezincane zenzelwe imiphetho ebukhali yokusika ukuze kuqinisekiswe ukusikeka okuhlanzekile futhi kuncishiswe ubungozi bokulimala kwezinto zokusebenza noma ama-burrs. Lokhu kubalulekile ezinhlelweni ezidinga ukuqedwa kwendawo ephezulu kanye nokunemba kobukhulu.

4. Ukukhishwa okuphumelelayo kwe-chip: Idizayini yomtshingo yezigayo ezincane zenzelwe ukukhishwa okuphumelelayo kwe-chip, ukuvimbela ukwakheka kwe-chip nokuqinisekisa ukusika okushelelayo. Ukukhishwa kwe-chip ngendlela efanele kusiza ukugcina ukusebenza kahle kwamathuluzi nokunciphisa amathuba okuphuka kwamathuluzi.

5. Amandla okusika ancishisiwe: Izigayo ezincane zenzelwe ukunciphisa amandla okusika, okubaluleke kakhulu uma usebenza ngezinto ezithambile noma ezincane. Amandla okusika aphansi asiza ukuvimbela ukuchezuka kwengcezu yokusebenza futhi anciphise amathuba okuguga noma ukuphuka kwamathuluzi.

6. Izinketho zokuhlanganisa: Izigayo zokugcina ze-tungsten carbide zingatholakala ngezingubo ezihlukahlukene, njenge-TiAlN, i-TiSiN, noma i-carbon-like diamond (DLC). Ama-coatings akhulisa ukusebenza kwethuluzi ngokunciphisa ukungqubuzana, ukuthuthukisa ukumelana nokuguga, nokuthuthukisa ukunqanyulwa kokushisa.

7. Izinketho zomtshingo eziningi: Izigayo ezincane zingaba nemitshingo emi-2, 3, noma emi-4. Inombolo yemitshingo ithinta ukuphuma kwe-chip kanye nokuzinza kwethuluzi ngesikhathi sokusika. Ukukhetha idizayini efanele yomtshingo incike ekusetshenzisweni okuqondile nezinto ezisetshenziswayo.

8. Izinketho ze-Shank: Izigayo zokugcina ezincane zingahlinzekwa ngezinhlobo ezahlukene ze-shank, kufaka phakathi ama-shank aqondile nama-tapered shanks. Ukukhethwa kohlobo lwe-shank kuncike kumphathi wamathuluzi womshini kanye nezidingo ezithile zokusethwa kwemishini.

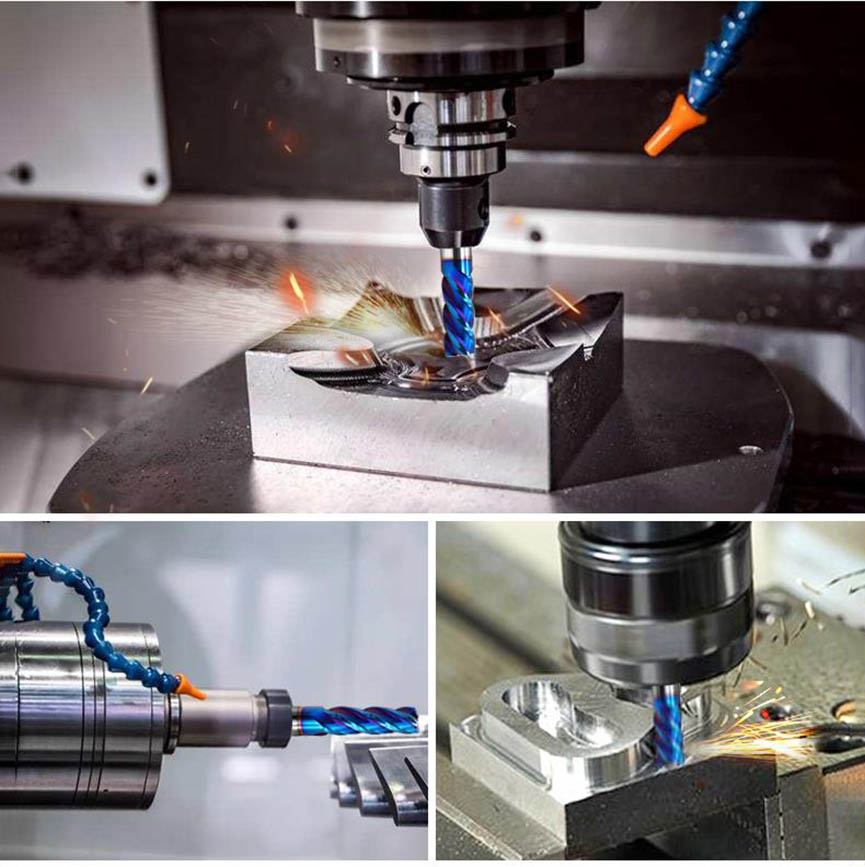

9. Ukuhlukahluka kohlelo lokusebenza: Izigayo ze-Micro tungsten carbide end zifanele izinhlelo zokusebenza eziningi ezahlukene, okuhlanganisa ukwenziwa kwemishini emincane, ukuqopha, ukukhonta, kanye nokubhola. Angasetshenziswa ezimbonini ezifana ne-electronics, medical, aerospace, kanye nobunjiniyela obunembayo.

10. Izinketho zokwenza ngokwezifiso: Abakhiqizi bavame ukuhlinzeka ngezinsizakalo zokwenza ngokwezifiso izigayo ezincane, okuvumela amakhasimende ukuthi acacise ububanzi, ubude bomtshingo, ubude bebonke, okokumboza, neminye imingcele ukuze kuhlangatshezwane nezidingo zabo zomshini ezithile.

Ikhwalithi ye-preminium tungsten carbide isikwele somshini wokugaya imininingwane

ifektri

| 2 Flutes Micro End Mill | ||||

| Into | Flute Diameter(d) | Ubude beFlute(I) | I-Shank Diameter(D) | Ubude Bebonke(L) |

| 0.2*0.4*4*50 | 0.2 | 0.4 | 4 | 50 |

| 0.3*0.6*4*50 | 0.3 | 0.6 | 4 | 50 |

| 0.4*0.8*4*50 | 0.4 | 0.8 | 4 | 50 |

| 0.5*1*4*50 | 0.5 | 1 | 4 | 50 |

| 0.6*1.2*4*50 | 0.6 | 1.2 | 4 | 50 |

| 0.7*1.4*4*50 | 0.7 | 1.4 | 4 | 50 |

| 0.8*1.6*4*50 | 0.8 | 1.6 | 4 | 50 |

| 0.9*1.8*4*50 | 0.9 | 1.8 | 4 | 50 |