I-Morse Taper Shank HSS End Mills

Izici

1. I-Morse Taper Shank: Isigayo sokugcina sine-shank eklanyelwe ukungena ku-Morse Taper spindle. Uhlelo lwe-Morse Taper luvumela ukukhwezwa okuphephile nokunembile kwesigayo sokugcina emshinini wokugaya.

2. I-High-Speed Steel (HSS): I-HSS iwuhlobo lwensimbi yensimbi evame ukusetshenziswa ekusikeni amathuluzi. Izigayo zokuphela kwe-HSS zaziwa ngokuqina kwazo, ukumelana nokushisa, nekhono lokumelana nesivinini esikhulu sokusika. Izigayo zokuphela kwe-HSS zifanele izinto eziningi ezihlukahlukene, okuhlanganisa insimbi ye-carbon, i-alloy steel, insimbi engagqwali, nezinsimbi ezingenayo insimbi.

3. Imitshingo: Umshini wokugaya uzoba nemitshingo eminingi ngobude bawo. Imitshingo yimisele eyi-helical noma eqondile ebusweni bomshini wokuphela. Imitshingo isiza ekukhishweni kwe-chip futhi ihlinzeka ngonqenqema lokususwa kwezinto. Inani lemitshingo lingahluka kuye ngohlelo lokusebenza, izinketho ezivamile zingaba imitshingo engu-2, 4, noma engu-6.

4. I-Cutting Edge Geometry: Izigayo zokuphela kwe-HSS ziza ngamajiyometri onqenqema ahlukahlukene, njenge-square end, ikhala lebhola, irediyasi yekhona, noma i-chamfer. Ijiyomethri ngayinye ifanele imisebenzi ethile yokugaya kanye nokuqedwa kwendawo oyithandayo.

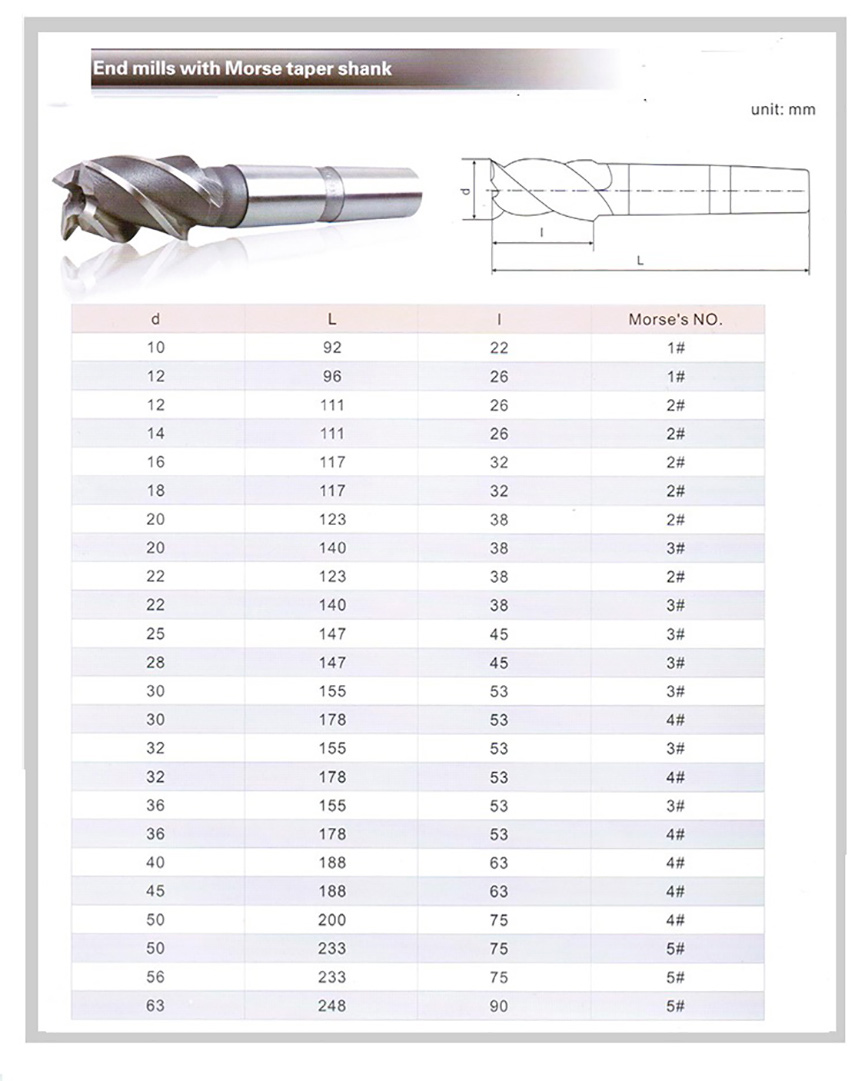

5. Ubude Bebonke kanye Nobude Bomtshingo: Ubude bubonke bubhekisela kubude obuphelele begayo lokugcina, kusukela ekugcineni konqenqema lokusika kuya ekugcineni kwe-shank. Ubude bomtshingo bubhekisela ubude bengxenye yokusika noma imitshingo. Ubude obuhlukene buyatholakala ukuze kuhlangatshezwane nokujula okuhlukene kokugaya kanye nezidingo zemvume.

6. Izinketho Zokuhlanganisa: Izigayo zokugcina ze-HSS zingase futhi zize nezinketho ezihlukahlukene zokuhlanganisa njenge-TiN, i-TiCN, noma i-TiAlN. Lezi zimbotshana zinikeza ukumelana nokuguga okuthuthukisiwe, ukuphila kwamathuluzi okwandisiwe, nokusebenza okungcono ezinhlelweni zokusika ezinejubane eliphezulu noma izinga lokushisa eliphezulu.

7. Osayizi Abajwayelekile: Izigayo zokuphela kwe-Morse Taper shank HSS zitholakala ngamasayizi ajwayelekile ahambisana negama le-Morse Taper (MT1, MT2, MT3, njll.). Lawa masayizi aqinisekisa ukulingana okufanele nokuhambisana nemishini yokugaya nama-spindle.

ifektri

Morse taper shank HSS end mill imininingwane

Izinzuzo

1. Ukukhweza Okuvikelekile Nokunembile: I-Morse Taper shank ihlinzeka ngokulingana okuvikelekile nokunembe ku-spindle, inciphisa ukuphuma futhi iqinisekise ukusika okunembile. Lokhu kusiza ukugcina ukunemba kwe-dimensional okungaguquki kanye nokuqedwa kwendawo ezingxenyeni zomshini.

2. Ukuguquguquka: Izigayo zokuphela kwe-Morse Taper shank HSS zitholakala ngezinhlobonhlobo zobukhulu namajiyometri, okuzenza zifanelekele imisebenzi yokugaya ehlukahlukene nezinhlobo zezinto ezibonakalayo. Lokhu kuguquguquka kuvumela uhla olubanzi lwezinhlelo zokusebenza ngaphandle kwesidingo sokusethwa kwamathuluzi amaningi.

3. Ukuqina Nokumelana Nokushisa: Izigayo zokugcina ze-HSS zaziwa ngokuqina kwazo kanye nokumelana nokushisa. Bangakwazi ukumelana nesivinini esikhulu sokusika futhi balondoloze ukusebenza kwabo kokusika ngisho nangaphansi kokushisa okunamandla okukhiqizwa ngesikhathi somshini. Lokhu kuqina kuhumushela empilweni yamathuluzi ende, kunciphisa imvamisa yokushintshwa kwamathuluzi kanye nesikhathi sokuphumula enqubweni yokwenza imishini.

4. Imali Eyongayo: Izigayo ze-HSS ngokuvamile zonga kakhulu uma ziqhathaniswa nezinye izinto zamathuluzi asebenza kahle kakhulu, njenge-carbide. Izigayo zokuphela kwe-HSS zinikeza ibhalansi enhle phakathi kokusebenza nezindleko, okuzenza zibe yinketho efanelekile yomshini wevolumu ephansi, izinto eziyinselele, noma izinhlelo zokusebenza ezinezidingo eziqinile kancane.

5. Ukuhambisana: Izigayo ze-Morse Taper shank ze-HSS zenzelwe ukuthi zihambisane nezinsimbi ezijwayelekile ze-Morse Taper ezivame ukutholakala emishinini yokugaya. Lokhu kusebenzisana kwenza ukusethwa kwethuluzi kube lula, kunciphisa isidingo sama-adaptha engeziwe, futhi kuvumela ukushintshashintsha kalula phakathi kwamathuluzi ahlukene.

6. Ikhono Lokulola Kabusha: Izigayo zokugcina ze-HSS zingalola kabusha kalula, zandise ukuphila kwazo okuwusizo futhi zinciphise izindleko zamathuluzi ngokuhamba kwesikhathi. Ngokulungiswa nokucijiswa okufanele, isigayo sokuphela kwe-HSS singaletha ukusebenza okungaguquki kanye nenani ngaphezu kwemijikelezo eminingi yokwenza imishini.

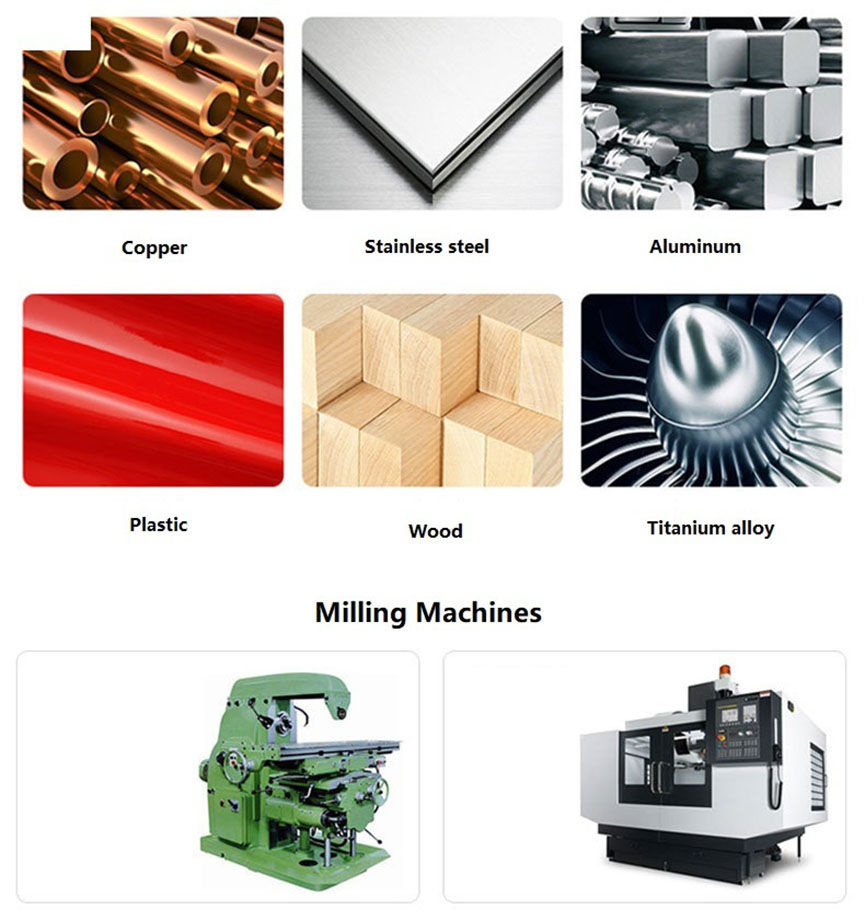

7. Ukuhambisana Kwezinto Ezibanzi: Izigayo zokuphela kwe-HSS zingakwazi umshini ngempumelelo inhlobonhlobo yezinto zokwakha, okuhlanganisa i-carbon steel, i-alloy steel, insimbi engagqwali, insimbi yokusansimbi, izinsimbi ezingezona ayoni, namapulasitiki. Lokhu kuguquguquka kubenza bafanelekele izimboni nezicelo ezahlukahlukene.