I-Precision Edge: Ukuvula Amandla E-TCT Saw Blades Kuzinhlelo Zokusebenza Zesimanje Zokusika

Udokotela Ohlinzayo Wezinto ezibonakalayo: Ukuthi I-TCT Technology Iguqula Kanjani Ukusika

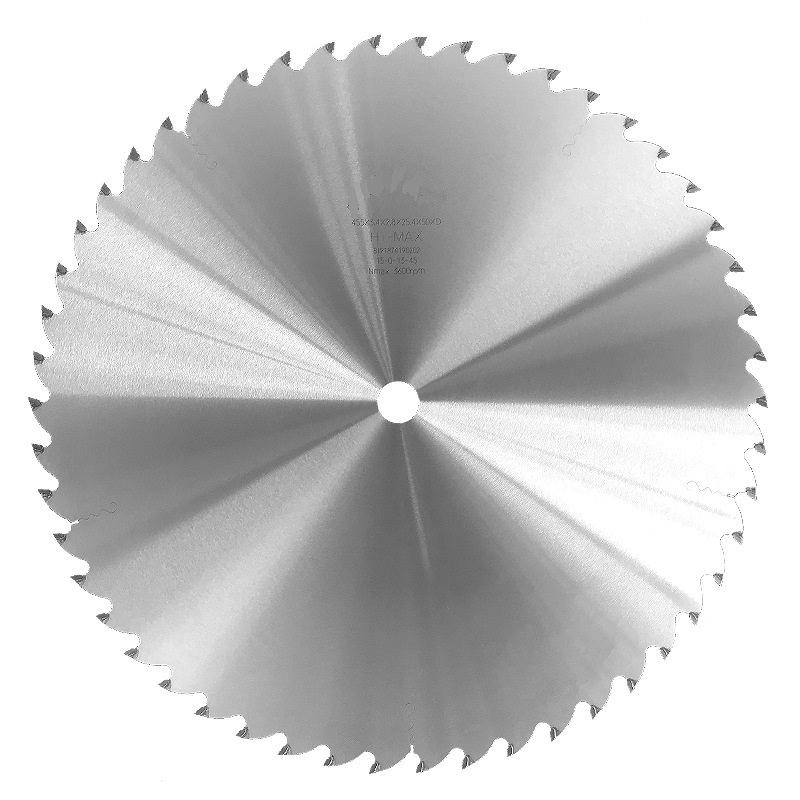

Ama-Tungsten Carbide Tipped (TCT) ama-saw blades amelela isiqongo sobuchwepheshe bokusika, ahlanganisa ukunemba kokuhlinzwa nokuqina kwezimboni. Ngokungafani nama-blade avamile, i-TCT ihlanganisa amazinyo e-micro-grain tungsten carbide—isigaba sezinto esinzima kunazo zonke esishoda ngamadayimane—abrazed noma aboshelwe emizimbeni yensimbi eqine kakhulu. Lo mklamo oyingxube uletha ukusebenza okungenakuqhathaniswa kulo lonke ukhuni, insimbi, inhlanganisela, nezinto ezikhethekile, okuwenza ube ngumpetha ongenambangi kuma-workshops ochwepheshe kanye nezilungiselelo zezimboni emhlabeni jikelele.

I-Core Engineering: I-Anatomy Yokusebenza Okuphakeme

1. Isayensi Yezinto Ezithuthukile

- Amazinyo e-Tungsten Carbide: Akhiwe nge-YG8-grade carbide noma okuhlukile okufakwe nge-cobalt, lawa macebiso agcina ubukhali obungu-8-10x ubude kunama-HSS ama-blade, ngisho nalapho esika izingodo eziqinile ezinamaqabunga (i-oki, i-teak) noma insimbi engagqwali .

- I-Anti-Friction Coatings: I-PVD (i-Physical Vapor Deposition) ezindwani ezindwangwini ezifana nochungechunge lwe-NYX SS inciphisa ukwakheka kokushisa ngo-40%, ivimbela ukunamathela kwezinto ezibonakalayo, futhi inwebe ukuphila kwe-blade 3x ekusikeni insimbi engagqwali.

- Ama-Shock-Absorbing Cores: Imizimba yensimbi eqine kakhulu ukuphuka (HRC 65) ivimbela ukungqubuzana phakathi nokusebenza kwetorque ephezulu, okubalulekile kunsimbi yokusaha ebandayo lapho izinga lokushisa lingaphezu kuka-600°F .

2. Izindlela Ezintsha ZeJiyomethri

- Amaphrofayili wezinyo:

- Amazinyo Amaphuzu Awukhonkolo: Kumaphaneli e-laminate/veneer, amazinyo ayi-conical adala ukusikeka okungenayo i-splinter ngokubeka amaphuzu angaphambili .

- I-Anti-Vibration Design: Ama-Spiral flute (ama-engeli angu-15–25° helix) ezinsinini zokhuni anika amandla ukuphuma okushelelayo kwe-chip, ehlisa umsindo ngo-15 dB futhi asuse ukudlidliza kocezu lokusebenza.

- I-Oblique Clamping: Ama-engeli angama-screw angu-45–90° anelungelo lobunikazi kuma-blade acishiwe athuthukisa ukuzinza, anciphise ukugudluzwa kwamazinyo ngesikhathi sokusika insimbi yesigaba esinzima.

3. Precision Bancing

- I-laser-calibrated tensioning iqinisekisa ukushibilika okungu-≤0.1mm, ngisho nakububanzi obungu-660mm. Lokhu kuvimbela ukuchezuka lapho kusikwa amashubhu ensimbi engagqwali anodonga oluwugqinsi, kugcina ukubekezelela okusikiwe ngaphakathi kuka-±0.2mm.

Izinzuzo Zokusebenza: Ngaphandle Kwejubane Nokuphila Isikhathi Eside

- I-Material Versatility

Uchungechunge olulodwa lwe-NYX blade lushintsha kalula phakathi:- Izinsimbi: Insimbi yesakhiwo, i-aluminium (ama-Bosun MAG350120L ama-blades asika i-aluminium ku-3,000 RPM), namashubhu angenasici.

- Izinhlanganisela Zezinkuni: Izinkuni eziqinile, i-MDF, nama-phenolic laminates ngaphandle kokudabula.

- Ukusebenza Kwezomnotho

- Ukuphila Okunwetshiwe: 2–3x isikhathi sokusebenza eside kunama-blade ajwayelekile—amahora angu-20–24 ku-sandalwood ebomvu ngokumelene namahora angu-8 ensimbi ye-carbon .

- Ukonga Amandla: Ijiyomethri yamazinyo elungiselelwe inciphisa ukudonsa kwamandla ngo-18% ezinhlelweni zokusika ezibandayo .

- Ikhwalithi Yobuso Nokuphepha

- I-Burr-Free Edges: Ubuchwepheshe bokusika amakhaza bugcina izinto zokusebenza zipholile, zivimbele ukuhlanekezela okushisayo futhi ziqede ukuqeda okwesibili .

- Ukulawula Uthuli: Imiklamo yomtshingo ovunguzayo ithwebula ama-chips angama-95%, enciphisa izinhlayiya ezihamba emoyeni .

Izixazululo Ezicacile Zohlelo: Ukufanisa Ama-blades Nemisebenzi

I-Industrial Metalworking

- I-Thick-Section Steel: Izindwani ze-NYX DS PVD (660mm) ezinamazinyo angu-180 zisika amabhilidi aqinile ku-60–380 m/min. Ukupholisa okumanzi kuyadingeka.

- Amashubhu Enga

I-Woodworking & Composites

- I-Hardwood Bandsawing: Amabhande e-TCT asika i-oki ku-25 m/s—ijubane eliphindwe kabili lamablade ekhabhoni—angashisi iqanda.

- I-CNC Machining: amabhithi erutha angu-25° spiral-angle anika amandla amanani okuphakelayo asheshayo angu-2x ekudwebeni kwe-MDF vs.

Okukhethekile Cutting

- Ukwenziwa kwe-Aluminium: Izindwani zamazinyo ayi-120 (i-Bosun MAG350120L) zivimbela ukugaya ngokushintshana kwamazinyo e-bevel.

- Amaphaneli Anwetshiwe: Ama-blade wamaphuzu alungisekayo adala ama-kerfs alungele i-veneer abe mncane njengo-2.0mm.

Ithebula: I-TCT Blade Selection Guide by Material

| Uhlobo Lwezinto | I-Blade Series | Imininingwane Ebalulekile | Izinga Lokuphakelayo Elilungile |

|---|---|---|---|

| Insimbi engagqwali | I-NYX SS PVD 6 | Amazinyo angu-180, Ø225–660mm | 40–80 m/min |

| Ukhuni oluqinile | I-TCT Spiral 5 | 15–25° helix, 0.45x core ratio | 8–12 m/min |

| I-Aluminium | I-Bosun MAG 8 | 120 amazinyo, Ø350mm | 25–40 m/min |

| Ukhonkolo/Ibha kabusha | I-SDS Plus 2 | 4-umtshingo, YG8 amathiphu carbide | 10–150 m/min |

Ukwandisa Impilo Ye-Blade: Amaphrothokholi Wokulungisa

- Isiyalo Sokupholisa: Ama-emulsions ancibilikayo ngamanzi adingekayo ekusikeni kwensimbi; ukusika okomile kugunyazwe kuphela ukhuni olungaphansi kuka-20mm ukujiya.

- Ukuhlola Izinyo: Hlola ukuphuka kwe-carbide njalo ngemva kwamahora angu-50 okusebenza—shintsha uma ukugunda kudlula u-0.3mm .

- Isitoreji: Hlala uqondile ezindaweni ezilawulwa yisimo sezulu; umswakama> 60% usheshisa ukugqwala kwensimbi.

I-future Edge: Ama-Smart Blades kanye Nezimboni 4.0

Ama-Next-gen TCT blades ashumeka ama-chips e-RFID ukuze alandelele ukuguga kwamazinyo namahora okusika, avumelaniswa namasistimu e-CNC ngezexwayiso zokulola ngokuzenzakalela. Ngaleso sikhathi, i-nano-layered carbide coatings (engaphansi kokuthuthukiswa) ithembisa impilo engu-5x ekusikeni kwe-titanium.

Isiphetho: Ukunemba njengokujwayelekile

I-TCT yabona izindwani zeqa indima yazo njengamathuluzi okusika nje—ayizinhlelo ezithuthukisiwe ezihlanganisa i-metallurgy, i-geometry, namandla. Ukuthi ukusika amashubhu angenasici ngokunemba kweleveli ye-micron noma ukuqopha ukhuni oluqinile olune-finesse yobuciko, kuletha ukusebenza kahle okungenasici. Kubakhiqizi abafuna ukukhiqizwa kwe-zero-waste noma abasebenza ngokhuni abafuna ukuqedwa okulungele igalari, ukutshala imali kubuchwepheshe obukhethekile be-TCT akuyona inketho—kuyisizinda sobuciko bokuncintisana.

Isikhathi sokuthumela: Jul-20-2025