I-Preminium Quality Tungsten Carbide Square End Mill ye-Super Hard Metal

Izici

1. Ukuqina nokuqina okuthuthukisiwe: Impahla ye-tungsten carbide esetshenziswa emshinini wokugcina ihlinzeka ngobulukhuni obuhle kakhulu nokuqina, ukuyivumela ukuthi imelane nokusebenza komshini wejubane eliphezulu kanye nempilo yamathuluzi eyandisiwe.

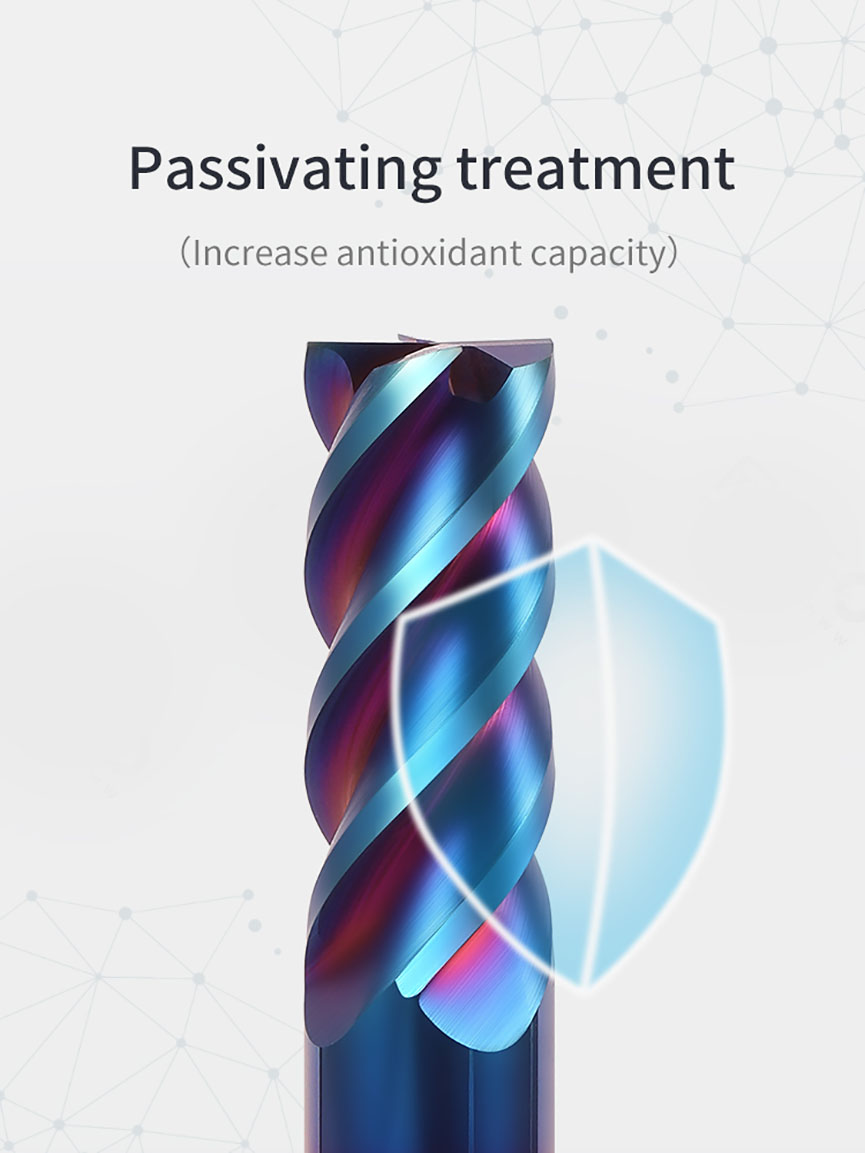

2. I-Nano blue coating: I-nano blue coating ifilimu elizacile, elibushelelezi elisetshenziswa endaweni yesigayo kusetshenziswa ubuchwepheshe bokunamathela obuthuthukisiwe. Lokhu kunamathela kuthuthukisa ukusebenza kwethuluzi ngokunciphisa ukungqubuzana nokukhiqiza ukushisa ngesikhathi sokusika, ukuthuthukisa ukuphuma kwe-chip, nokumelana nokuguga nokugqwala.

3. Ukwenyuka kwesivinini sokusika: I-nano blue coating inciphisa ukungqubuzana phakathi kwesigayo sokuphela kanye nesiqeshana somsebenzi, okuvumela isivinini sokusika esiphezulu. Lokhu kuholela ekukhiqizeni okuthuthukisiwe nokusebenza kahle ekusebenzeni kwemishini.

4. Ukumelana nokushisa okuphezulu: I-nano eluhlaza okwesibhakabhaka ithuthukisa ukumelana nokushisa kwesigayo sokugcina, iyenze ikwazi ukumelana namazinga okushisa aphezulu akhiqizwa ngesikhathi sokusika. Lokhu kunciphisa ukuwohloka kwamathuluzi futhi kwandisa isikhathi sempilo yethuluzi.

5. Ukumelana nokugqokwa okuhle kakhulu: I-nano blue coating inikeza ukumelana nokugqokwa okukhethekile, inciphisa izinga lokugqoka kwethuluzi futhi inwebe impilo yalo yesevisi. Lokhu kuphumela ekusebenzeni kokusika okungaguquki kanye nesikhathi esincishisiwe sokushintsha kwamathuluzi.

6. Ukukhishwa kwe-chip okuthuthukisiwe: Indawo ebushelelezi ye-nano blue coating ikhuthaza ukukhishwa okungcono kwe-chip, ukuvimbela ukwakheka kwe-chip nokunciphisa ingozi yokuphuka kwamathuluzi noma ukulimala.

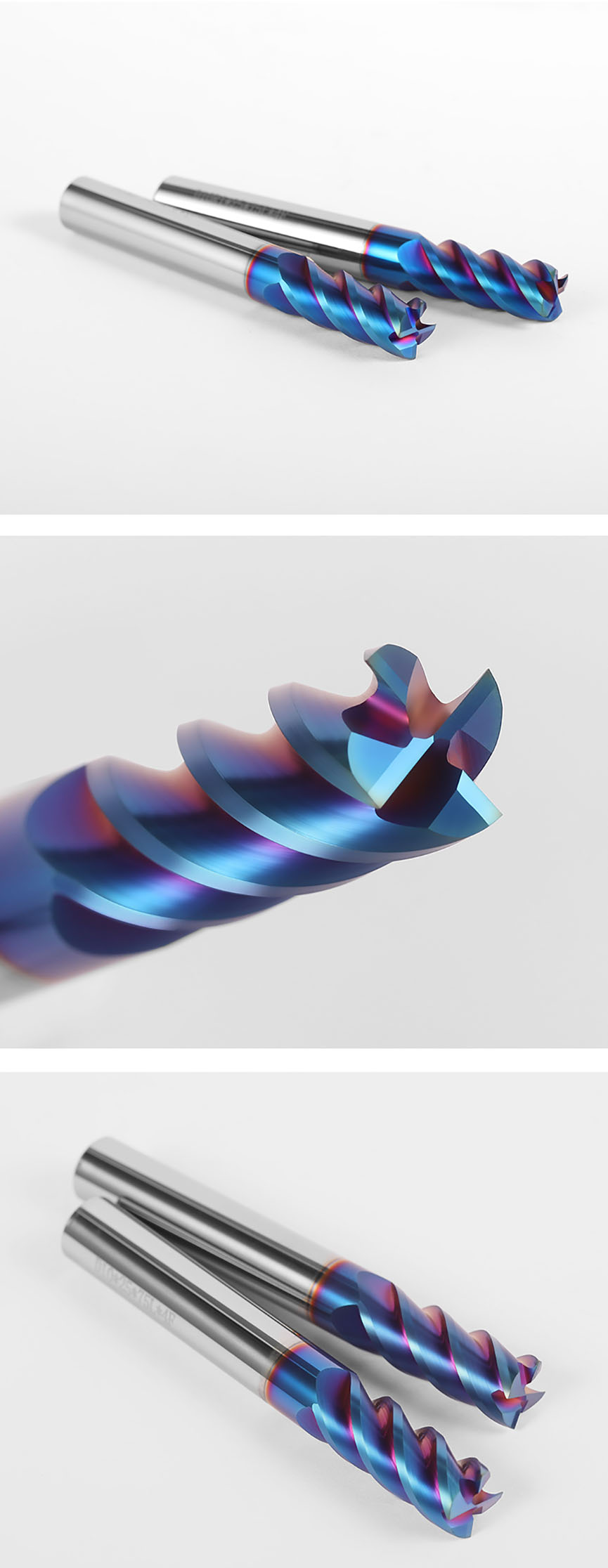

7. Ukusika okunembile nokunembile: Inhlanganisela yezinto eziphezulu ze-tungsten carbide kanye ne-nano blue coating ivumela ukusika okunembile nokunembile, okuholela ekuqedeni okuhlanzekile nokubushelelezi ku-workpiece.

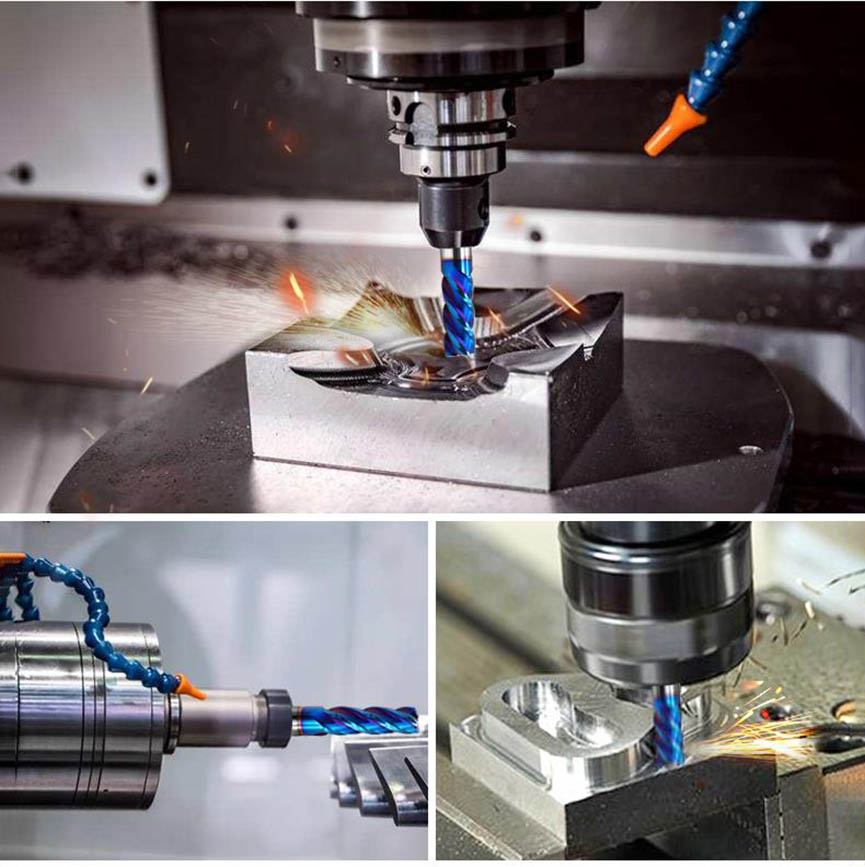

8. Ukuguquguquka: Izigayo zesikwele ze-Tungsten carbide ezine-nano blue coating zingasetshenziselwa uchungechunge olubanzi lwemisebenzi yokugaya, okuhlanganisa ukugoqa, ukuqeda, ukukhonkotha, kanye nokwenza iphrofayela ezintweni ezihlukahlukene njengensimbi, insimbi engagqwali, i-aluminium, nokunye.

Ikhwalithi ye-preminium tungsten carbide isikwele somshini wokugaya imininingwane

Umdwebo wemininingwane yomkhiqizo

Izinzuzo

1. Impilo yamathuluzi ethuthukisiwe: Inhlanganisela yekhwalithi ephezulu ye-tungsten carbide kanye ne-nano blue coating kukhulisa kakhulu impilo yamathuluzi omshini wokugcina uma kuqhathaniswa nezinguqulo ezingamboziwe. Lokhu kubangela ukunciphisa izindleko zamathuluzi kanye nokukhiqiza okuthuthukisiwe

2. Isivinini sokusika esithuthukisiwe: I-nano eluhlaza okwesibhakabhaka inciphisa ukungqubuzana nokukhiqiza ukushisa ngesikhathi sokusika, okuvumela isivinini sokusika esiphezulu. Lokhu kusiza ukukhulisa ukusebenza kahle kwemishini nokunciphisa izikhathi zokujikeleza.

3. Ukwenyuka kokungagugi: I-nano blue coating ithuthukisa ukumelana nokuguga kwemishini yokuphela, inikeze isivikelo ekuhuzukeni futhi inwebe ukuphila kwethuluzi. Lokhu kusho izinguquko ezivamile zamathuluzi kanye nesikhathi esincishisiwe sokuphumula.

4. Ukuqedwa okuphezulu okuphezulu: I-nano eluhlaza okwesibhakabhaka inciphisa unqenqema olwakhiwe futhi inciphisa amandla okusika, okuholela ekuqedeni okubushelelezi nokunembe ngaphezulu kwendawo yokusebenza. Lokhu kuzuzisa kakhulu izinhlelo zokusebenza ezidinga ikhwalithi ephezulu yendawo.

5. Ukukhishwa kwe-chip nokusebenza kahle kokupholisa: I-nano blue coating ithuthukisa ukugeleza kwe-chip nokusabalalisa okupholisayo, ivimbela ukuvinjelwa kwe-chip nokuqinisekisa ukuchithwa okuphumelelayo kokushisa. Lokhu kusiza ukugcina ukusebenza okuhle kakhulu kokusika nokunciphisa ingozi yokwehluleka kwamathuluzi.

6. Ukumelana nokugqwala: I-nano blue coating inikeza isithiyo esivikelayo ekugqwaleni, sinwebe ukuqina kwesigayo sokugcina futhi sinciphise amathuba okwehluleka ngaphambi kwesikhathi ngenxa yokuwohloka kwamakhemikhali.

7. Ukuguquguquka kwezinhlelo zokusebenza zemishini: Izigayo zesikwele zekhwalithi ye-tungsten carbide yesikwele esine-nano eluhlaza okwesibhakabhaka zingasetshenziswa ezintweni ezihlukahlukene, okuhlanganisa insimbi engagqwali, izinsimbi eziqinile, insimbi ekhonjiwe, nezinsimbi ezingenayo insimbi. Zilungele ukusebenza ngokugobayo, ukuqeda, kanye ne-contouring, enikeza ukuguquguquka kwezinhlelo zokusebenza zomshini.

8. Ukuqina kwethuluzi okuthuthukisiwe: I-nano blue coating isiza ukunciphisa ukudlidliza futhi ithuthukise ukuqina kwamathuluzi ngesikhathi sokusika, okuholela ekuthembekeni kwenqubo ephakeme kanye nokunemba okuthuthukisiwe kobukhulu.

9. Izinzuzo zemvelo: Ukusetshenziswa komshini wokuphela wokusebenza okuphezulu nge-nano blue coating kunganciphisa imingcele yokusika, njengamandla okusika kanye nesivinini sokusika. Lokhu kungaholela ekongeni amandla kanye nokusetshenziswa kwezinsiza eziphansi, kube nomthelela enqubweni yokwenza imishini eluhlaza futhi esimeme.

| Ububanzi beblade (mm) | Ubude be-blade (mm) | Okugcwele(mm) | I-Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |