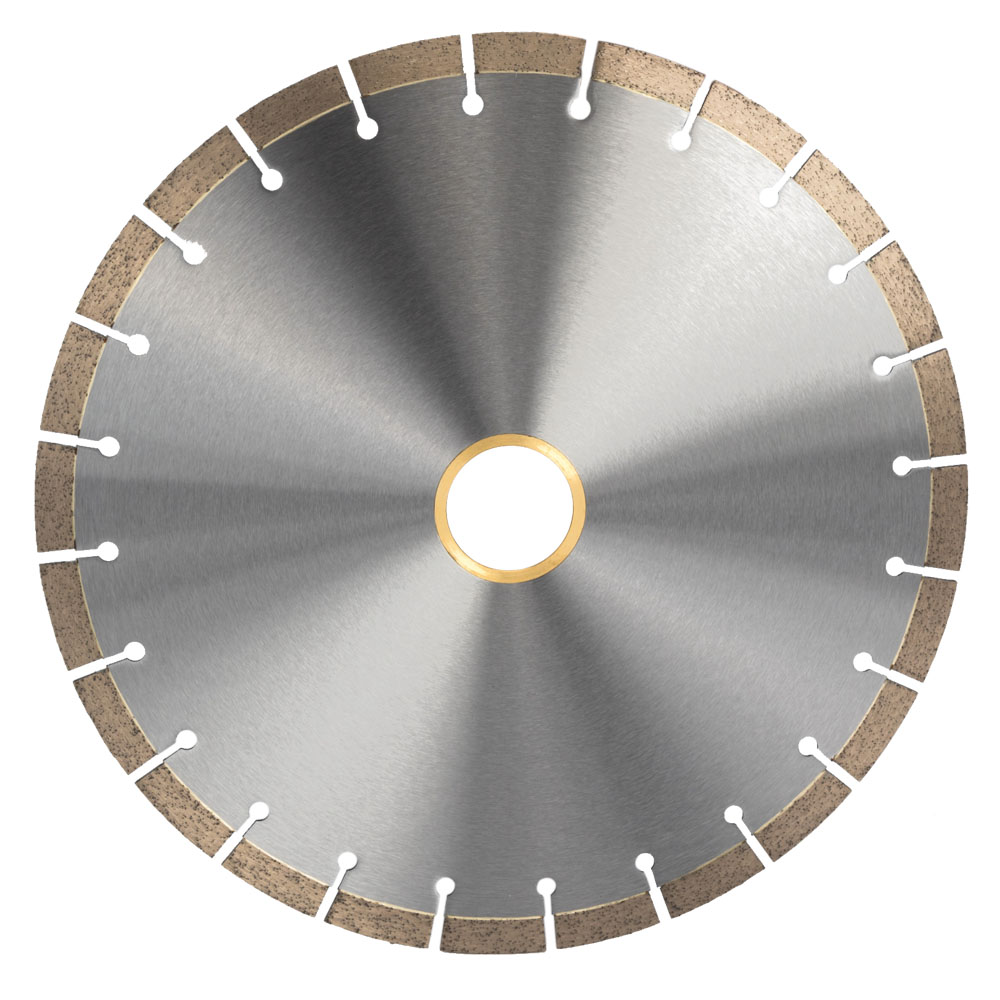

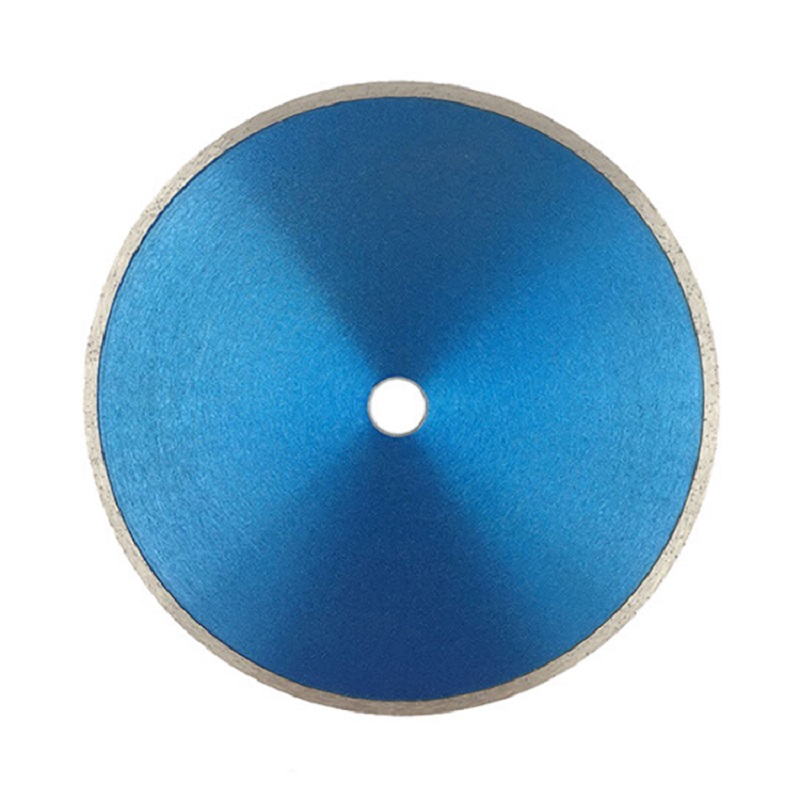

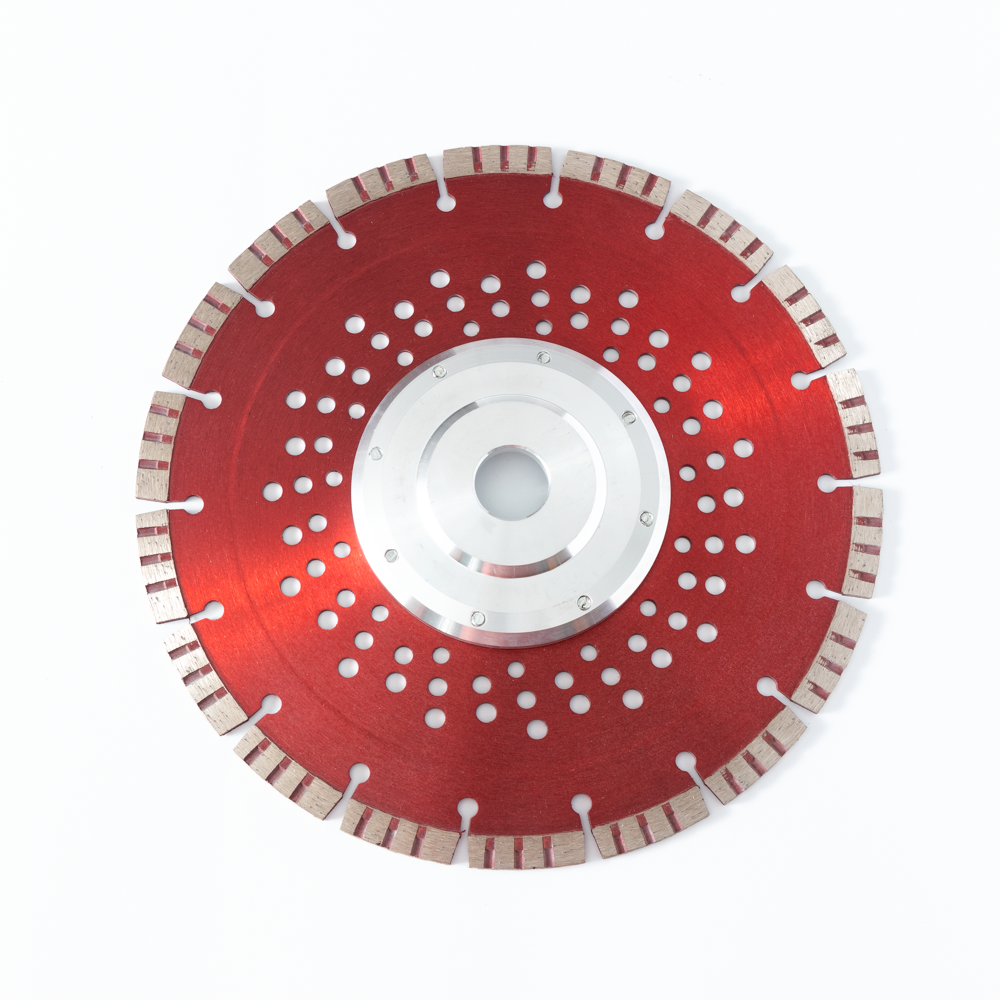

I-Sintered Diamond circular saw Blade yokusika itiyela

izinzuzo

1.Izindwani zesaha zedayimane ezisikiwe zaziwa ngokuhlala kwazo okukhethekile nokuqina, okuzenza zilungele ukugwazwa kokusikwa kwetiyela. Inqubo ye-sintering idala isibopho esiqinile phakathi kwephuzu ledayimane ne-blade, iqinisekisa ukusebenza okuhlala isikhathi eside.

I-2.Sintered diamond saw blades zenzelwe ukusika i-asphalt ngokuphumelelayo, okuholela ekusebenzeni okusheshayo, okushelelayo kokusika. Lokhu kusiza ukwandisa umkhiqizo kanye nokunciphisa izindleko zabasebenzi.

3.Ukuklanywa kwama-blade edayimane e-sintered ngokuvamile kuhlanganisa izici ezikhuthaza ukuchithwa kokushisa okuphumelelayo ngesikhathi sokusika. Lokhu kusiza ukuvimbela i-blade ekushiseni ngokweqile, kunciphisa ingozi yokungqubuzana noma ukulimala, futhi kwandise impilo ye-blade.

4. Ngenkathi ikakhulukazi esetshenziselwa ukusika itiyela, amasaha edayimane enziwe nge-sintered nawo ayasebenza ekusikeni ezinye izinto ezilumayo ezifana nokhonkolo omusha, izitini namatshe, okuhlinzeka ngezindlela ezihlukahlukene kosonkontileka nochwepheshe bezokwakha.

5.Amathiphu edayimane ane-Sintered asiza ukunciphisa ukuchotshozwa, ukuqinisekisa ukusikeka okuhlanzekile, okunembayo okuholela endaweni eqediwe yekhwalithi ephezulu enezidingo ezincane zokucubungula emva kokucubungula.

6.Ama-blade edayimane ane-Sintered ngokuvamile adinga ukulungiswa okuncane kanye nemvamisa yokushintshwa kwe-blade kunezinye izinhlobo ze-blade, okusiza ukunciphisa izindleko zokusebenza zizonke kanye nesikhathi sokuphumula.

I-7.Impilo ende kanye nokusebenza kahle okuphezulu kwama-saw blades edayimane e-sintered kubenza kube ukukhetha okungabizi kakhulu kokusika i-asphalt, okuhlinzeka ngokulinganisela okuhle phakathi kokutshalwa kwezimali kokuqala nokusebenza kwesikhathi eside.

Ukuhlolwa Komkhiqizo

INDAWO YEFEKHI

| Ububanzi(mm) | Ubude Besegimenti(mm) | Ububanzi Bengxenye(mm) | Ubude bengxenye(mm) | Inombolo |

| 200 | 40 | 3.2 | 10 | 14 |

| 250 | 40 | 3.2 | 10 | 17 |

| 300 | 40 | 3.2 | 10 | 21 |

| 350 | 40 | 3.2 | 10 | 24 |

| 400 | 40 | 3.6 | 10 | 28 |

| 450 | 40 | 4.0 | 10 | 32 |

| 500 | 40 | 4.0 | 10 | 36 |

| 550 | 40 | 4.6 | 10 | 40 |

| 600 | 40 | 4.6 | 10 | 42 |

| 700 | 40 | 5.0 | 10 | 52 |

| 750 | 40 | 5.5 | 10 | 56 |

| 800 | 40 | 5.5 | 10 | 46 |