Solid Carbide Machine Reamer nge Spiral Flute

Izinzuzo

1. Ukuqina Okuphakeme Nokumelana Nokugqoka: I-Carbide eqinile iyinto eqinile kakhulu futhi ehlala isikhathi eside engamelana nesivinini sokusika futhi igcine umkhawulo wayo wokusika isikhathi eside. Lobu bunzima nokumelana nokugqoka kwenza ama-reamers omshini we-carbide alungele ukusetshenziswa ekusetshenzisweni okudingayo nezinto zokwakha.

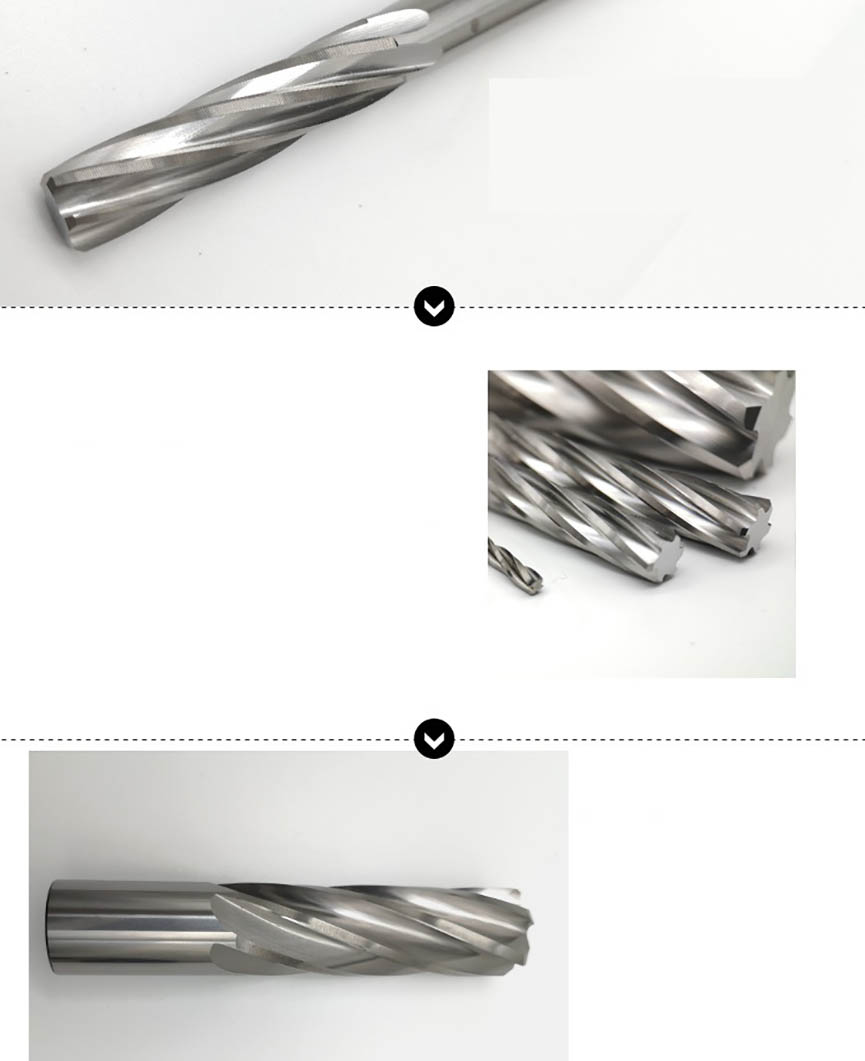

2. Ukukhishwa Kwe-Chip Okuhle Kakhulu: Idizayini yomtshingo ovunguzayo yemishini eqinile ye-carbide reamers ivumela ukukhishwa okuphumelelayo kwe-chip phakathi nenqubo yokubuyisela kabusha. Ama-spiral flute asiza ekuvimbeleni ukuvaleka kwe-chip noma ukuminyana, athuthukise ukusebenza nokukhiqiza kwe-remer.

3. Isivinini Sokusika Esikhulisiwe: Ngenxa yokuqina kwabo okuphakeme, ama-reamers omshini oqinile we-carbide angasetshenziswa ngesivinini esiphakeme sokusika kunezinye izinto zokuvuselela. Lokhu kuvumela ukusebenza kabusha okusheshayo nangempumelelo, ukunciphisa isikhathi somshini kanye nokukhulisa umkhiqizo.

4. I-Surface Ethuthukisiwe Qeda: Izinsimbi eziqinile zomshini we-carbide ezinemitshingo ezungezayo zikhiqiza indawo ebushelelezi embobeni eyenziwe ngomshini. Ukucushwa komtshingo okuvunguzayo kusiza ukunciphisa ukuxoxa nokudlidliza phakathi nenqubo yokusika, okuholela ekuthuthukisweni kwekhwalithi yembobo nokunemba.

5. Ukuphila Kwethuluzi Elide: Izixhumi zemishini eqinile ye-carbide zinempilo yamathuluzi ende uma kuqhathaniswa nezinye izinto zokuvuselela kabusha. Ukumelana nokugqoka okuphezulu nokuqina kwazo kuzivumela ukuthi zimelane nezimo ezinzima ezihlangatshezwana nazo ngesikhathi sokuvuselela kabusha, kunciphisa imvamisa yoshintsho lwamathuluzi kanye nesikhathi sokuphumula esihlobene.

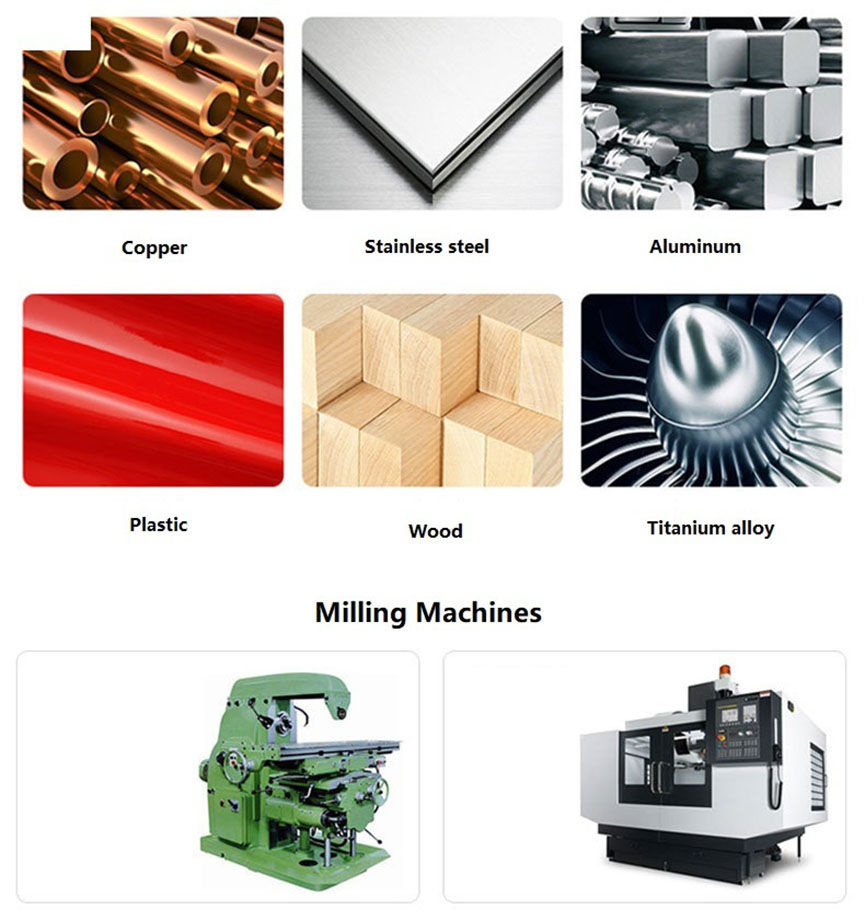

6. Ukuguquguquka: Imishini eqinile ye-carbide reamers enomtshingo ovunguzayo ingasetshenziswa ezinhlobonhlobo zezinto, ezihlanganisa izinsimbi, izinsimbi ezingenasici, insimbi ekhonjiwe, nezinsimbi ezingenayo insimbi. Bangakwazi ukusingatha kokubili ukusikeka okuphazamisekile nokusebenza okuqhubekayo kokuphinda kwenziwe kabusha ezintweni ezihlukahlukene zokusebenza.

7. Ukuqina Kwe-Reamer Eyengeziwe: Idizayini yomtshingo ovunguzayo yalezi zixhumi kusiza ukuthuthukisa ukuzinza phakathi nenqubo yokusika. Lokhu kunciphisa ukuchezuka, kuvimbela ingxoxo, futhi kuqinisekisa ukudalwa kwezimbobo ezinembe kakhudlwana.

8. Ukunemba Kobukhulu: Imishini eqinile ye-carbide reamers ikhiqizwa ukuze ikwazi ukubekezelela okuqinile, ihlinzeka ngokunemba okuhle kakhulu kwe-dimensional kanye nokuvumelana. Lokhu kubenza bafanelekele izinhlelo zokusebenza ezidinga ububanzi bembobo obunembile kanye nokubekezelelana okuqinile.

9. Ukugcinwa Kwethuluzi Elincishisiwe: Ngenxa yokuqina kwazo okukhethekile nokumelana nokugqokwa, izivuseleli zemishini eqinile ye-carbide zidinga ukucijiswa nokugcinwa okungavamile okungavamile uma kuqhathaniswa nezinye izinhlobo ze-reamer. Lokhu kunciphisa inani lesikhathi nomzamo ochithwa ekulungisweni kwamathuluzi futhi kuvumela ukwenziwa kwemishini okungaphazamiseki okwengeziwe.

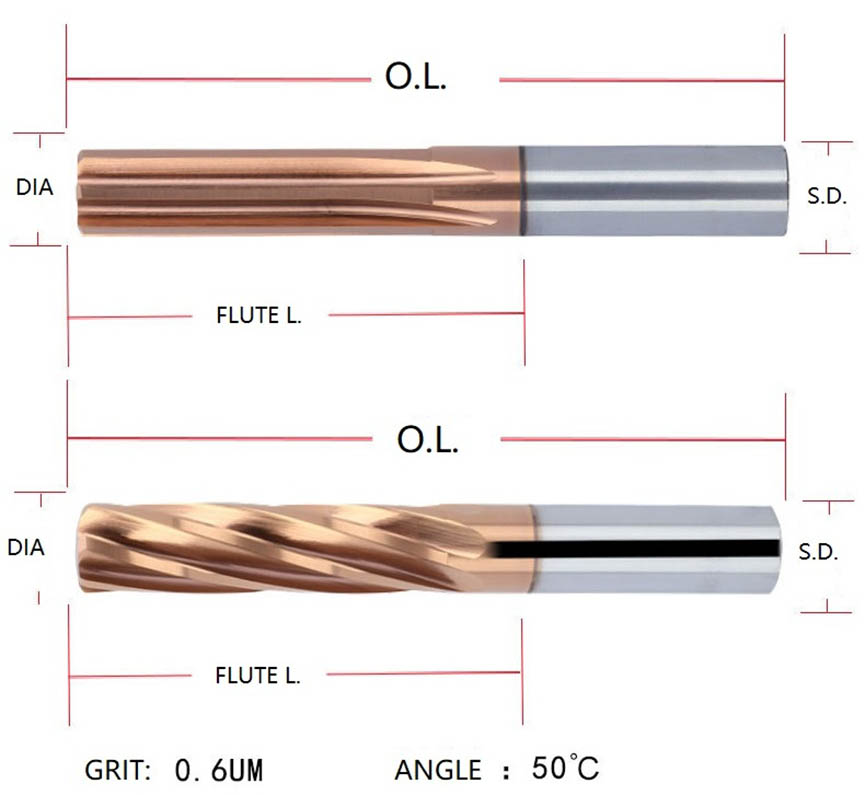

UMBUKISO WOMKHIQIZO

| I-DIA | UFLUTE L. | SHANK DIA | KONKE L. | AMA-FLUTES | |

| 3 | 30 | 3D | 60L | 4F | |

| 4 | 30 | 4D | 60L | 4F | |

| 5 | 30 | 5D | 60L | 6F | |

| 6 | 30 | 6D | 60L | 6F | |

| 8 | 40 | 8D | 75L | 6F | |

| 10 | 45 | 10D | 75L | 6F | |

| 12 | 45 | 12D | 75L | 6F | |