Solid Carbide roughing End Mill

Izici

1. Izinga eliphakeme lokususa impahla: Izigayo zokuphela kwe-Tungsten carbide ziklanywe ngemitshingo embalwa uma kuqhathaniswa nezigayo ezijwayelekile zokuphela. Lokhu kuvumela umthwalo we-chip omkhulu kanye nesenzo sokusika esinolaka, okuholela emazingeni aphezulu okususwa kwezinto. Zilungele ukususa ngokushesha inani elikhulu lezinto ekusebenzeni okuqinile.

2. Ukuqina okuphezulu nokumelana nokugqoka: I-Tungsten carbide yaziwa ngobulukhuni bayo obungavamile kanye nokumelana nokugqoka. Lokhu kwenza izigayo eziqinile ezenziwe nge-tungsten carbide zihlale isikhathi eside, ngisho nalapho kwenziwa izinto eziqinile njengensimbi engagqwali, i-alloy steel, noma insimbi ecijile.

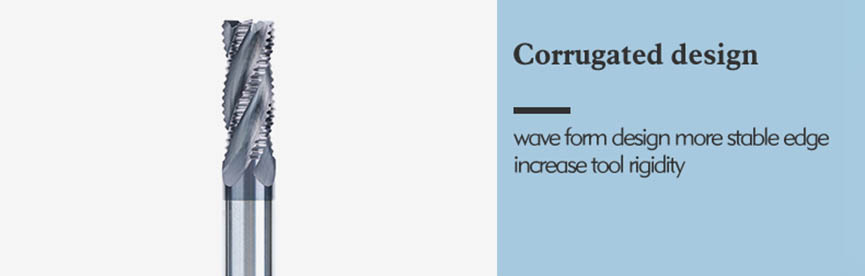

3. Idizayini yezinyo elimahhadla: Izigayo ezigaywayo zivame ukuba namazinyo amakhulu futhi ahlukaniswe kabanzi uma kuqhathaniswa nezinye izigayo. Lo mklamo usiza ukufeza ukukhishwa okuphumelelayo kwe-chip futhi uvimbele ukuvinjelwa kwe-chip, uqinisekise ukusebenza okushelelayo kokusika.

4. Izinqamuleli ze-chip: Ezinye izigayo ze-tungsten carbide eziheshayo zingase zibe nama-chip breaker noma ama-chip splitter emaphethelweni okusika. Lezi zici zisiza ukuphula ama-chips amade abe yizingcezu ezincane, ezilawulekayo, ezikhuthaza ukukhishwa okungcono kwama-chip kanye nokunciphisa ubungozi bokulimala kwezingcezu zokusebenza.

5. Ukumelana nokushisa okuphezulu: Ukumelana nezinga lokushisa eliphezulu kwe-tungsten carbide kuvumela izigayo zokugcina ezimangelengele ukuthi zimelane nokushisa okukhiqizwa ngesikhathi sokususwa kwezinto ezinzima. Lokhu kumelana nokushisa kusiza ukuvimbela ukuwohloka kwamathuluzi noma ukwehluleka kwamathuluzi ngaphambi kwesikhathi, kuqinisekisa ukuphila kwamathuluzi okude.

6. I-helix eguquguqukayo noma idizayini yephimbo eguquguqukayo: Ezinye izigayo zokugcina ezimaholoholo zine-helix eguquguqukayo noma idizayini yephimbo eguquguqukayo kumtshingo wazo. Lesi sici sisiza ukunciphisa ukuxoxa nokudlidliza phakathi nenqubo yokusika, okuholela ekuqedweni okuthuthukisiwe kwendawo kanye nokwanda kokuqina kwamathuluzi.

7. Izinketho zokuhlanganisa: Izigayo zokugcina eziqinile zingagcotshwa ngezingubo ezihlukahlukene, njenge-TiAlN, i-TiCN, noma i-AlTiN. Lezi zimbotshana zithuthukisa ukusebenza kwethuluzi ngokunciphisa ukungqubuzana, ukwandisa ukugeleza kwe-chip, nokuthuthukisa ukumelana nokuguga. Ukukhethwa kwe-coating efanele kuncike kuhlelo lokusebenza oluthile kanye nempahla yokusebenza.

8. Ukwakhiwa okuqinile: Izigayo ze-Tungsten carbide zokugcina zakhiwe ngendlela eqinile futhi ehlala isikhathi eside ukuze zimelane nezidingo zomsebenzi onzima. Zenzelwe ukuphatha amandla aphezulu okusika futhi zinikeze ukuzinza ngesikhathi sokususwa kwezinto ezinzima.

9. Izinketho ze-Shank: Izigayo ze-Tungsten carbide roughing end ziyatholakala ngezinketho ezihlukahlukene ze-shank, kuhlanganise nama-shank aqondile, ama-Weldon shanks, noma ama-Morse taper shanks. Ukukhethwa kwe-shank kuncike kumphathi wamathuluzi womshini kanye nezidingo ezithile zokusethwa komshini.

10. Amajiyometri wamathuluzi: Izigayo zokugcina eziqinile zingaba nejiyometri yethuluzi elithile ukuze kuthuthukiswe ukusebenza kokusika. Lawa majiometri angase afake phakathi ukukhushulwa kobubanzi bomgogodla, irediya yekhona eqinisiwe, noma amalungiselelo akhethekile onqenqema okuthuthukisa amandla nokusebenza kwamathuluzi ngesikhathi sokusebenza kanzima.

Isibonisi semininingwane

IFEKHI