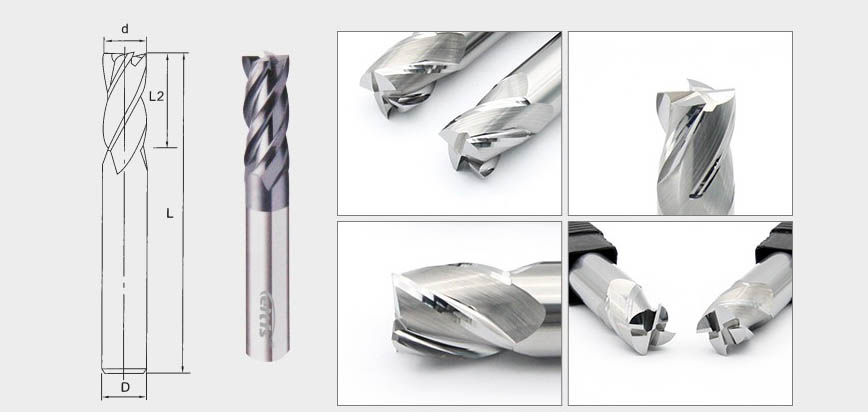

I-Solid Carbide Square End Mills yomshini ojwayelekile

Izici

1. Material: Izigayo eziqinile zesikwele se-carbide zenziwe ngocezu olulodwa lwempahla ye-carbide, eqinisekisa ukuqina okuphezulu nokumelana nokuguga.

2. Ukuqina: I-Carbide yaziwa ngobulukhuni bayo obungavamile. Izigayo eziqinile zesikwele se-carbide zingamelana nesivinini esikhulu sokusika futhi zigcine ubukhali bazo isikhathi eside uma ziqhathaniswa nezinye izinto.

3. Ukunemba: Izigayo zesikwele se-carbide eziqinile zenzelwe ukunemba engqondweni. Bayakwazi ukukhiqiza ukusikeka okunembile nokuhlanzekile, okuholela kuma-workpieces anembile futhi aphezulu.

4. Ukuguquguquka: Lezi zigayo zokuphela zingasetshenziswa ezintweni ezihlukahlukene, okuhlanganisa izinsimbi ezisansimbi nezingeyona insimbi, amapulasitiki, nezinhlanganisela. Lokhu kuguquguquka kubenza bafanelekele uhla olubanzi lwezinhlelo zokusebenza zemishini.

5. Ukusebenza kahle: Izigayo eziqinile zesikwele ze-carbide ziklanywe ngemitshingo eminingi, ezithuthukisa ukuphuma kwe-chip futhi zinciphise amathuba okuvala. Lokhu kuthuthukisa ukusebenza kahle kwemishini kanye nokukhiqiza okuphelele.

6. Ukumelana nokushisa: I-Carbide inezinto ezinhle kakhulu zokumelana nokushisa, okuvumela izigayo eziqinile zesikwele se-carbide ukumelana namazinga okushisa akhiqizwa ngesikhathi sokusika ngaphandle kokulahlekelwa ubulukhuni noma ubukhali.

7. Ubude bokuphila: Ngenxa yokuqina kwazo okuphezulu nokuqina, izigayo eziqinile zesikwele se-carbide zinesikhathi eside sokuphila uma ziqhathaniswa nezinye izinhlobo zezigayo zokugcina. Lokhu kubangela ukushintshwa kwamathuluzi ambalwa, kunciphisa isikhathi sokuphumula nezindleko.

8. Ukuqina okuphezulu: Izigayo eziqinile ze-carbide zinokuqina okuphezulu, okusho ukuthi mancane amathuba okuba zigobe noma ziphambuke ngesikhathi sokusebenza komshini. Lokhu kuqina kuholela ekuzinzeni kokusika okuthuthukisiwe kanye nokunemba kobukhulu.

9. Izinketho zokuhlanganisa: Izigayo eziyisikwele ze-carbide eziqinile zingaphinda zimbozwe ngezingubo ezihlukahlukene ezifana ne-TiN, i-TiCN, ne-TiAlN, ezithuthukisa ngokwengeziwe ukusebenza kwazo ngokunciphisa ukungqubuzana, ukwandisa ukuphila kwamathuluzi, nokuthuthukisa ukuphuma kwe-chip.

10. Ijiyomethri ye-Cutting-edge: Izigayo eziqinile zesikwele se-carbide ziyatholakala kumajiyometri ahlukile, njengemiklamo eqondile, ye-helical, ne-variable helix. Lezi geometries zinikeza izici ezihlukene zokusika futhi zibhekelela izidingo ezithile zomshini.

Isibonisi semininingwane

IFEKHI

Izinzuzo

1. Ukuqina: Izigayo eziqinile zesikwele se-carbide zaziwa ngokuqina kwazo okukhethekile. Impahla ye-Carbide imelana nokugqokwa futhi ingamelana nesivinini esikhulu sokusika nezinto ezihuquzelayo, okuholela ekuphileni kwamathuluzi okude.

2. High Speed Machining: Izigayo eziqinile zesikwele se-carbide zingenza ngokuphumelelayo imisebenzi yemishini yesivinini esikhulu ngenxa yokuqina kwazo nokumelana nokushisa. Lokhu kuvumela ukwanda kokukhiqiza kanye nezikhathi ezimfishane zemishini.

3. Ukukhishwa Kwe-Chip Okuhle Kakhulu: Amacilongo asezindaweni eziqinile zesikwele se-carbide aklanyelwe ukuthuthukisa ukuphuma kwe-chip. Lokhu kusiza ukuvimbela ukwakheka kwe-chip futhi kuqinisekisa ukusika okushelelayo, kunciphisa ubungozi bokulimala kwamathuluzi noma ukonakala kwengcezu yokusebenza.

4. I-Surface Ethuthukisiwe Qeda: Izigayo eziqinile zesikwele se-carbide zikhiqiza ukusikeka okuhlanzekile nokunembe, okuholela ekuqedeni okuphezulu kwendawo yokusebenza. Lokhu kuqeda isidingo sezinqubo zokuqeda ezengeziwe, ukonga isikhathi nezindleko.

5. Ukuguquguquka: Izigayo eziqinile zesikwele ze-carbide zilungele inhlobonhlobo yezinto zokwakha, okuhlanganisa izinsimbi, amapulasitiki, nezinhlanganisela. Lokhu kuguquguquka kuzenza zilungele izimboni ezahlukahlukene, kusukela kwezezimoto kuye emkhathini.

6. Ukuzinza Okuthuthukisiwe: Izigayo eziqinile zesikwele se-carbide zifaka ukuqina okuphezulu, okunciphisa ukuchezuka kwamathuluzi futhi kuthuthukise ukuzinza kokusika. Lokhu kubangela ukunemba kwe-dimensional okuthuthukisiwe kanye namathuba ancishisiwe okuphuka kwamathuluzi.

7. Umshini Wokunemba: Imiphetho ebukhali yokusika izigayo eziqinile zesikwele se-carbide zivumela umshini onembile futhi onembile. Lokhu kubalulekile ezinhlelweni ezidinga ukubekezelelana okuqinile kanye nemininingwane eyinkimbinkimbi.

8. Ukumelana Nokushisa: Izigayo eziqinile ze-carbide zingamelana namazinga okushisa aphezulu akhiqizwa ngesikhathi somshini. Lokhu kumelana nokushisa kuvimbela ithuluzi ukuthi lingathambisa noma lilahlekelwe izakhiwo zalo zokusika, liqinisekisa ukusebenza okungaguquki.

9. Izinguquko Zethuluzi Ezincishisiwe: Izigayo eziqinile zesikwele se-carbide zinesikhathi eside sethuluzi uma kuqhathaniswa nezinye izinto, ezinciphisa isidingo sokushintsha njalo kwamathuluzi. Lokhu kuholela ekwandeni kokusebenza kahle kokukhiqiza kanye nokuncipha kwesikhathi sokuphumula.

10. Ukusebenza Kwezindleko: Nakuba ekuqaleni kubiza kakhulu, izigayo eziqinile ze-carbide square zinikeza ukonga izindleko zesikhathi eside ngenxa yempilo yazo eyandisiwe yamathuluzi namandla okusebenza okuphezulu. Lokhu kubenza babe ukukhetha okungabizi kakhulu kwemisebenzi yokukhiqiza.

| Ububanzi beblade (mm) | Ubude be-blade (mm) | Okugcwele(mm) | I-Shank (mm) |

| 1.0 | 3 | 50 | 4 |

| 1.5 | 4 | 50 | 4 |

| 2.0 | 6 | 50 | 4 |

| 2.5 | 7 | 50 | 4 |

| 3.0 | 8 | 50 | 4 |

| 3.5 | 10 | 50 | 4 |

| 4.0 | 11 | 50 | 4 |

| 1.0 | 3 | 50 | 6 |

| 1.5 | 4 | 50 | 6 |

| 2.0 | 6 | 50 | 6 |

| 2.5 | 7 | 50 | 6 |

| 3.0 | 8 | 50 | 6 |

| 3.5 | 10 | 50 | 6 |

| 4.0 | 11 | 50 | 6 |

| 4.5 | 13 | 50 | 6 |

| 5.0 | 13 | 50 | 6 |

| 5.5 | 13 | 50 | 6 |

| 6.0 | 15 | 50 | 6 |

| 6.5 | 17 | 60 | 8 |

| 7.0 | 17 | 60 | 8 |

| 7.5 | 17 | 60 | 8 |

| 8.0 | 20 | 60 | 8 |

| 8.5 | 23 | 75 | 10 |

| 9.0 | 23 | 75 | 10 |

| 9.5 | 25 | 75 | 10 |

| 10.0 | 25 | 75 | 10 |

| 10.5 | 25 | 75 | 12 |

| 11.0 | 28 | 75 | 12 |

| 11.5 | 28 | 75 | 12 |

| 12.0 | 30 | 75 | 12 |

| 13.0 | 45 | 100 | 14 |

| 14.0 | 45 | 100 | 14 |

| 15.0 | 45 | 100 | 16 |

| 16.0 | 45 | 100 | 16 |

| 17.0 | 45 | 100 | 18 |

| 18.0 | 45 | 100 | 18 |

| 19.0 | 45 | 100 | 20 |

| 20.0 | 45 | 100 | 20 |

| 22.0 | 45 | 100 | 25 |

| 25.0 | 45 | 100 | 25 |