T thayipha okuqinile kweCarbide End Mill

Izici

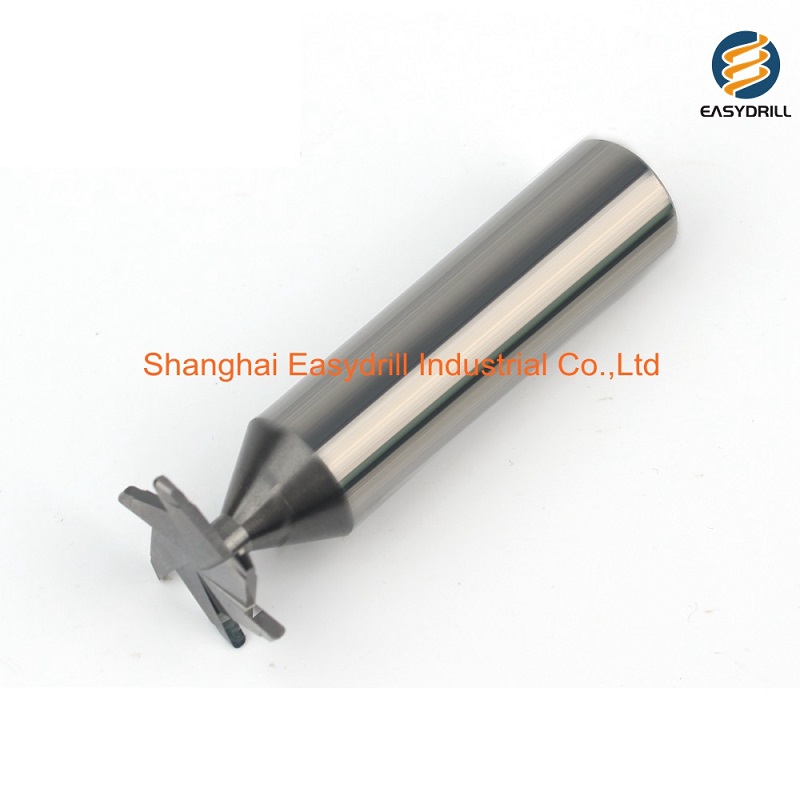

Izigayo eziqinile ze-carbide ezimise okwe-T zaziwa ngokusebenza kwazo okuphezulu kanye nekhono lokusika ngokunemba. Ezinye zezici ezibalulekile zezigayo zokugcina eziqinile ze-carbide ezimise okwe-T zifaka:

1. Isakhiwo se-carbide esiqinile: Izigayo zokugcina ezimise okwe-T zenziwe nge-carbide eqinile, enobunzima obuhle kakhulu, ukumelana nokugqoka nokumelana nokushisa, ngaleyo ndlela andisa impilo yamathuluzi futhi ithuthukise ukusebenza.

2. Ijiyomethri Eguquguqukayo: Izigayo zokugcina ezimise okuka-T zivame ukuba namajiyometri aguquguqukayo asiza ngokukhipha ama-chip asebenzayo, anciphise amandla okusika, futhi athuthukise ukuqedwa kwendawo.

3. I-engeli ephezulu ye-helix: I-engeli ephezulu ye-helix yemishini yokuphela yohlobo lwe-T ingafinyelela ukususwa kwe-chip okuphumelelayo futhi ithuthukise ukusebenza kokusika, ikakhulukazi ezinhlelweni zokusebenza zemishini yesivinini esikhulu.

4. Idizayini yokusika isikhungo: Izigayo eziningi zokuphela kohlobo lwe-T ziklanywe ngomsebenzi wokusika ophakathi nendawo, okuvumela ukusika nokuzulazula.

5. Izinketho zokuhlanganisa eziningi: Izigayo zokuphela kohlobo lwe-T zinezinketho eziningi zokuhlanganisa, njenge-TiAlN, i-TiCN ne-AlTiN, ezingathuthukisa ukumelana nokugqoka, ukunciphisa ukungqubuzana nokuthuthukisa impilo yamathuluzi.

6. I-Precision ground cutting edge: Izigayo zokuphela kohlobo lwe-T zenziwa ngokunemba kwemiphetho yokusika ukuze kuqinisekiswe ukusebenza kokusika okunembile nokungaguquki.

7. Osayizi abahlukahlukene kanye nokucushwa: Izigayo zokugcina ezimise okuka-T zitholakala ngobukhulu obuhlukahlukene, ubude be-groove, nokucushwa ukuze kuhlangatshezwane nezidingo zomshini ezahlukene kanye nezinhlelo zokusebenza.

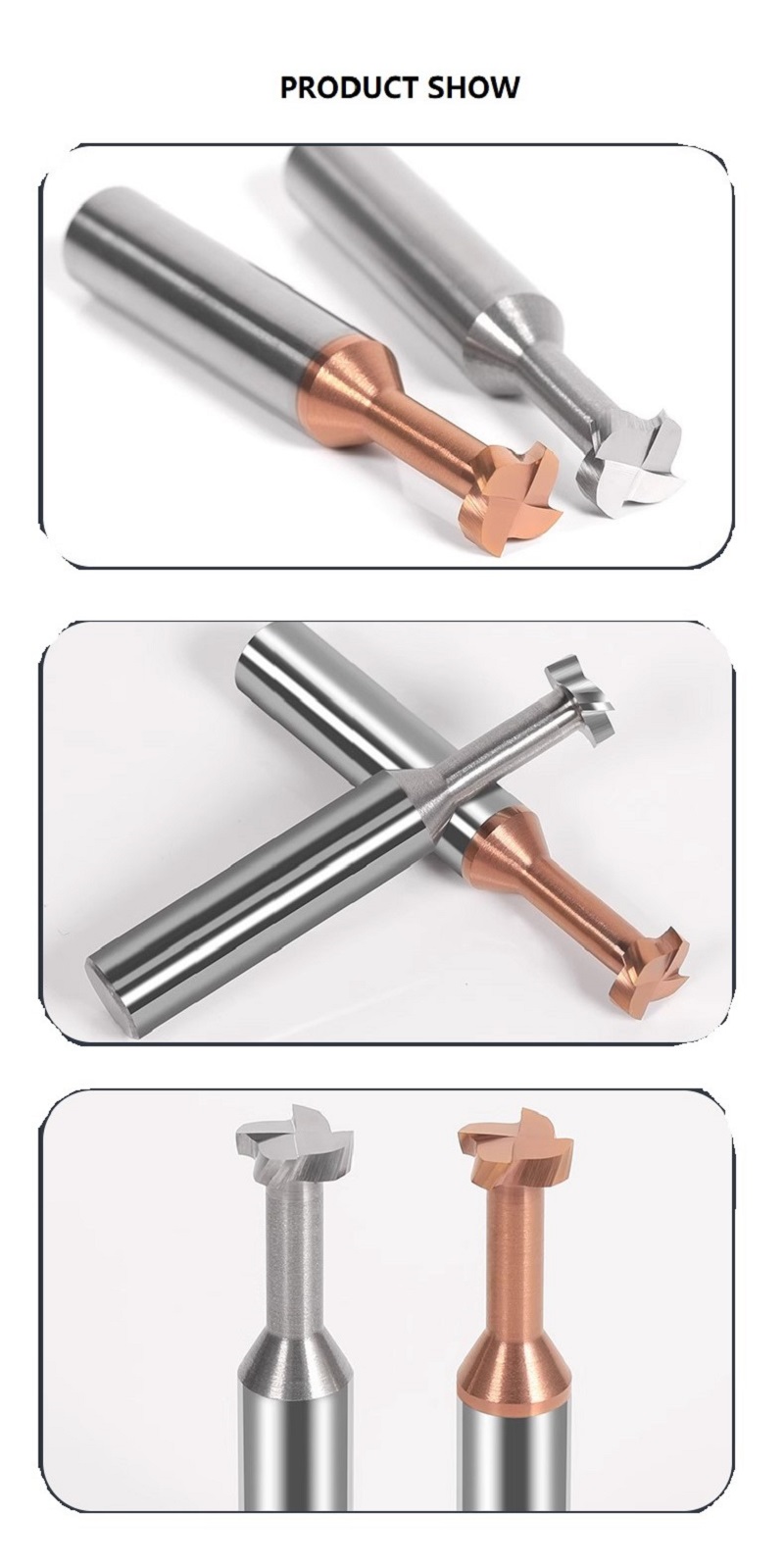

UMBUKISO WOMKHIQIZO

UMBUKISO WOMKHIQIZO