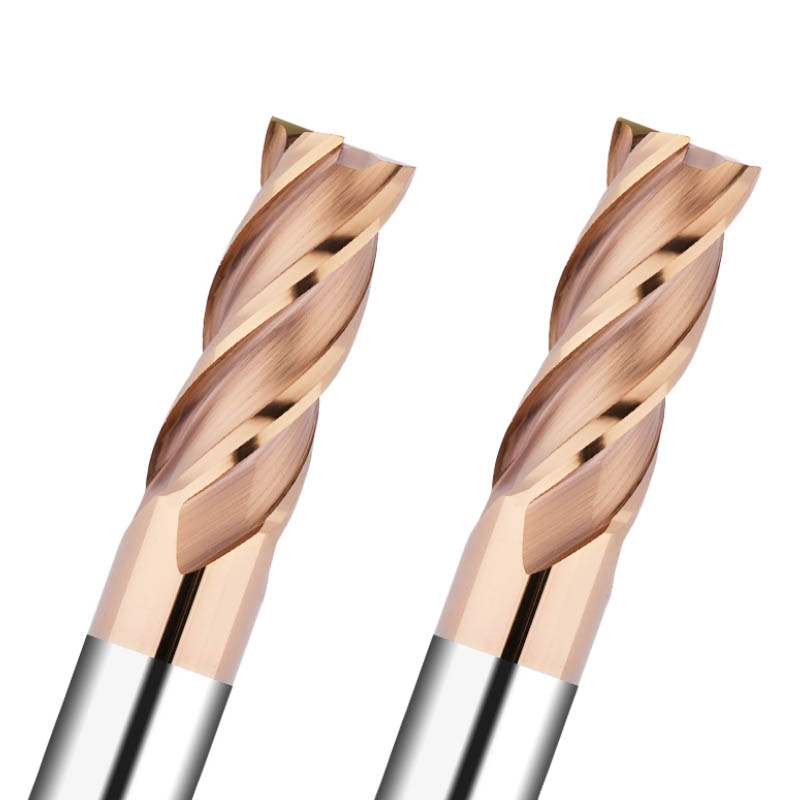

I-Tungsten Carbide Corner Radius End Mill

Izici

1. Ukusebenza okuthuthukisiwe kokusika: Ikhona eliyindilinga lesigayo sokugcina linciphisa ukugxila kwengcindezi futhi linciphise amathuba okuphuka noma ukuphuka. Lokhu kuphumela esenzweni sokusika esishelelayo nempilo yamathuluzi ethuthukisiwe uma kuqhathaniswa nezigayo zesikwele.

2. Ukuqedwa kwendawo okuthuthukisiwe: Ikhona eliyindilinga lensimbi yokugcina lisiza ukunciphisa izimpawu zamathuluzi futhi likhiqize ukuqedwa okungcono kwendawo yokusebenza. Lokhu kubaluleke kakhulu uma kwenziwa izingxenye ezithambile noma ezinembe kakhulu.

3. Amandla okugaya ikhonsathi: Idizayini yerediyasi yekhona ivumela ukusebenza kahle kwe-contour noma ukwenza iphrofayela. Ingalandela ngokushelelayo amaphrofayili ocezu lomsebenzi olugobile noma angajwayelekile, inikeze ukuguquguquka okwengeziwe ekukhiqizeni izimo eziyinkimbinkimbi.

4. Amandla angeziwe nokuzinza: Izigayo zokuphela kwerediyasi esekhoneni le-tungsten carbide ziklanywa ngesisekelo esibanzi kanye nemiphetho yokusika eqinile, ethuthukisa amandla nokuzinza kwazo ngesikhathi sokusika. Lokhu kubangela ukunemba okungcono kanye nokuchezuka okuncishisiwe, ikakhulukazi ezinhlelweni zokugaya ezisindayo noma ezinolaka.

5. Ukuthuthukiswa kokuphuma kwe-chip: Ikhona eliyindilinga le-end mill lisiza ekuphumeni okuphumelelayo kwe-chip, ukuvimbela ukupakishwa kwe-chip nokuvumela ukugeleza okungcono kokupholisa. Lokhu kusiza ukugcina ukusebenza kokusika okungaguquki futhi kunciphisa ingcuphe yokusikwa kabusha kwe-chip noma ukulimala kwamathuluzi.

6. Izinketho eziningi zomtshingo: Izigayo zokuphela kwerediyasi esekhoneni le-Tungsten carbide ziyatholakala ngezinketho ezihlukahlukene zomtshingo, njengemitshingo emi-2, 3, noma emi-4. Ukukhethwa kwenani lemitshingo kuncike ekusetshenzisweni okuqondile, impahla, kanye nemingcele yokusika oyifunayo.

7. Izinketho zokumboza: Izigayo zokuphela kwerediyasi esekhoneni le-carbide ye-Tungsten zingagcotshwa ngezingubo ezihlukene, okuhlanganisa i-TiAlN, i-TiCN, noma i-AlTiN, ukuze kuthuthukiswe ukusebenza kwazo. Ama-coatings athuthukisa impilo yamathuluzi, anciphise ukungqubuzana, futhi anikeze ukumelana nokushisa, kuye ngokunamathela okuqondile okusetshenzisiwe.

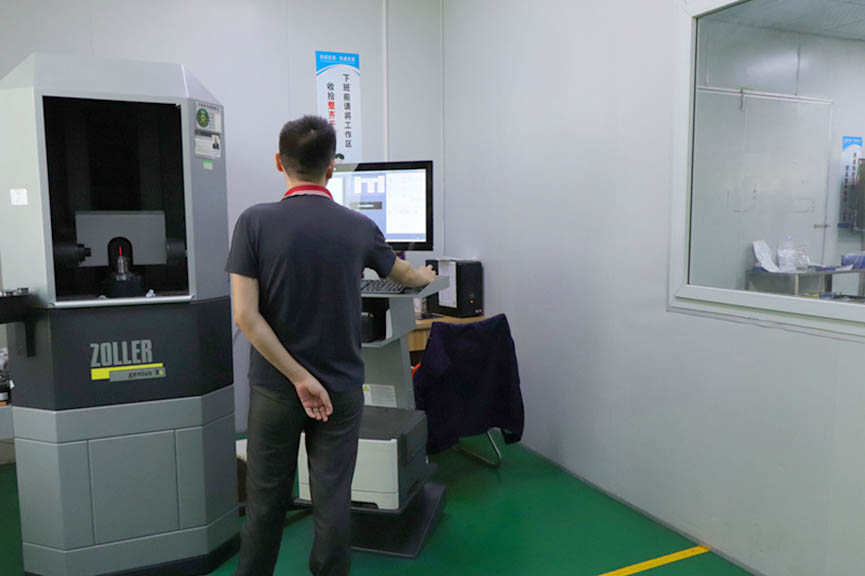

IFEKHI