I-Tungsten Carbide Tapered End Mill

Izici

1. Amakhono omshini ahlukahlukene: Izigayo zokuphela kwe-tapered zingasetshenziselwa imisebenzi eyahlukene yomshini, okuhlanganisa ukukhonta, ukucwilisa, nokubhola. Idizayini ye-taper ivumela ukususwa kwezinto ezisebenzayo kanye nokusika okunembile ngezindlela eziningi.

2. Ukufinyelela nokufinyeleleka okuthuthukisiwe: Ukuma kwe-tapered yesigayo sokugcina kunikeza ukufinyelela okungcono ezindaweni okunzima ukufinyelela kuzo futhi kuvumela imisebenzi yokugaya ejulile. Lokhu kunenzuzo ikakhulukazi lapho usebenza ngezingxenye eziyinkimbinkimbi noma ngaphakathi kwemigodi.

3. Ukukhishwa kwe-chip okuthuthukisiwe: Idizayini yomtshingo yezigayo ezicijile isiza ukukhipha ama-chips kahle. Ngevolumu yawo enkulu yomtshingo kanye nesikhala esibanzi, asebenza kahle ekususeni ama-chip endaweni yokusika, enciphisa ubungozi bokunqanyulwa kwe-chip kanye nokwenza ngcono ukusebenza kwamathuluzi kukonke.

4. Ukuqina nokuqina okukhulayo: Izigayo zokuphela kwe-tungsten carbide tapered zenzelwe ukunikeza ukuzinza nokuqina okwandisiwe ngesikhathi sokusika. Umumo oyi-conical usiza ukusabalalisa amandla okusika ngokulinganayo, ukunciphisa ukudlidliza nokunciphisa ukuchezuka, okuholela ekunembeni okuthuthukisiwe nokuqedwa kwendawo.

5. Ama-engeli amaningi e-taper atholakalayo: Izigayo zokuphela kwe-tapered ziza ngama-engeli ahlukene we-taper, afana no-3°, 5°, 7°, nangaphezulu. Ukukhethwa kwe-engeli ye-taper kuncike ezidingweni ezithile zohlelo lokusebenza, njengobubanzi obufunwayo bokusika kanye nezinto ezenziwa ngomshini.

6. Izinketho zokuhlanganisa: Izigayo zokuphela kwe-tungsten carbide tapered zingagcotshwa ngezingubo ezihlukahlukene, njenge-TiAlN, TiCN, noma i-AlTiN, ukuze zithuthukise ukusebenza kwazo. Izingubo zokumboza zinikeza ukuphila kwamathuluzi okwandisiwe, ukungqubuzana okuncishisiwe, nokumelana nokushisa okuthuthukisiwe, kuye ngokunamathela okuqondile okusetshenzisiwe.

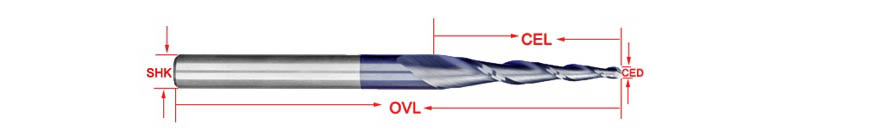

Isibonisi semininingwane

IFEKHI

| Imitshingo emibili i-spiral tapered ball nose end mill | |||||

| Okusebenzayo: I-Aluminium, ipulasitiki, ingxenye yepulasitiki, izingxenye zethusi, ingxubevange ye-aluminium, isikhunta sensimbi engagqwali, ukhuni | |||||

| NO | SHK | 1/2 CED(mm) | CEL | I-OVL | |

| 2fbn30.2515 | 3.175 | 0.25 | 15 | 38.5 | |

| 2fbn30.515 | 3.175 | 0.5 | 15 | 38.5 | |

| 2fbn30.7515 | 3.175 | 0.75 | 15 | 38.5 | |

| 2fbn31.015 | 3.175 | 1 | 15 | 38.5 | |

| 2fbn40.2515 | 4 | 0.25 | 15 | 50 | |

| 2fbn40.515 | 4 | 0.5 | 15 | 50 | |

| 2fbn40.7515 | 4 | 0.75 | 15 | 50 | |

| 2fbn41.015 | 4 | 1 | 15 | 50 | |

| 2fbn40.2520.5 | 4 | 0.25 | 20.5 | 50 | |

| 2fbn40520.5 | 4 | 0.5 | 20.5 | 50 | |

| 2fbn40.7520.5 | 4 | 0.75 | 20.5 | 50 | |

| 2fbn41.020.5 | 4 | 1 | 20.5 | 50 | |

| 2fbn60.2520.5 | 6 | 0.25 | 20.5 | 50 | |

| 2fbn60.520.5 | 6 | 0.5 | 20.5 | 50 | |

| 2fbn60.7520.5 | 6 | 0.75 | 20.5 | 50 | |

| 2fbn61.020.5 | 6 | 1 | 20.5 | 50 | |

| 2fbn602530.5 | 6 | 0.25 | 30.5 | 75 | |

| 2fbn60.530.5 | 6 | 0.5 | 30.5 | 75 | |

| 2fbn60.7530.5 | 6 | 0.75 | 30.5 | 75 | |

| 2fbn61.030.5 | 6 | 1 | 30.5 | 75 | |

| 2fbn61.530.5 | 6 | 1.5 | 30.5 | 75 | |

| 2fbn62.030.5 | 6 | 2 | 30.5 | 75 | |

| 2fbn80.547 | 8 | 0.5 | 47 | 85 | |

| 2fbn81.047 | 8 | 1 | 47 | 85 | |

| 2fbn81.547 | 8 | 1.5 | 47 | 85 | |

| 2fbn82047 | 8 | 2 | 47 | 85 | |

| 2fbn80.560 | 8 | 0.5 | 60 | 100 | |

| 2fbn81.060 | 8 | 1 | 60 | 100 | |

| 2fbn81.560 | 8 | 1.5 | 60 | 100 | |

| 2fbn82.060 | 8 | 2 | 60 | 100 | |

| 2fbn10270 | 10 | 2 | 70 | 110 | |

| 2fbn12270 | 12 | 2 | 70 | 120 | |