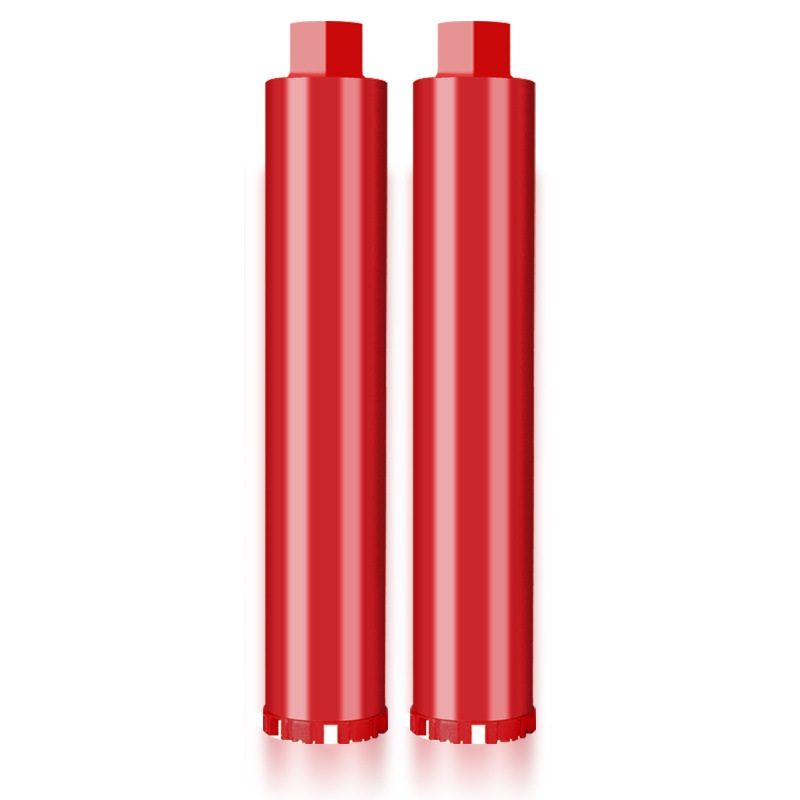

Vacuum Izingcezu Zokubhoboza Zedayimane Le-Brazed Kokhonkolo Netshe

Izinzuzo

1. I-vacuum brazing iyinqubo yokukhiqiza ehlanganisa izinhlayiya zedayimane ngokuqondile emzimbeni wensimbi yokubhoboza kusetshenziswa amazinga okushisa aphezulu kanye nomfutho we-vacuum. Lokhu kubangela isibopho esiqinile nesihlala isikhathi eside phakathi kwegrit yedayimane kanye ne-drill bit, okuqinisekisa ukusebenza okuhle kakhulu kokusika kanye nokususwa kwezinto ezisebenzayo.

2. Inqubo ye-vacuum brazing ikhiqiza isibopho esivikelekile nesihlala isikhathi eside phakathi kwedayimane nebhilidi lokubhoboza. Lokhu kwandisa kakhulu ubude besikhathi be-drill bit uma kuqhathaniswa nezinye izinhlobo zama-core drill bits. Ngokucophelela nokusetshenziswa okufanele, izingcezu zokubhola eziwumgogodla wedayimane elivalwe nge-vacuum zinganikeza ukusebenza okungaguquki nokuthembekile esikhathini eside.

3. Izinhlayiya zedayimane ezinamathiselwe ebusweni be-drill bit zinikeza isenzo sokusika esisheshayo nesinolaka. Lokhu kusho ukuthi i-vacuum brazed diamond core drill bits ingangena ngokushesha nangempumelelo endaweni eqinile kakhonkolo neyetshe, inciphise isikhathi sokumba nokwandisa umkhiqizo.

4. Lezi zingcezu zokubhoboza zilungele ukusetshenziswa okubanzi, okuhlanganisa imigodi yokubhoboza kukhonkolo, itshe, imabula, igwadle, amathayela e-ceramic, nezinye izinto eziqinile. Idizayini yazo eguquguqukayo izenza zihambisane nemishini yokumba ehlukahlukene, njengemishini yokumba eyingqikithi, ama-angle grinder, kanye nokubhola ngesandla.

5. Izingcezu zokubhoboza eziwumgogodla wedayimane levacuum ziklanyelwe ukunciphisa ukuchotshozwa nokuqhekeka phakathi nenqubo yokumba. Ubukhali begrit yedayimane nokunemba kusika phakathi kwezinto ngokuhlanzekile, kunciphisa ubungozi bokulimala endaweni ezungezile.

6. Inqubo ye-vacuum brazing ithuthukisa ukumelana nokushisa kwe-drill bit, ukuyivumela ukuthi imelane namazinga okushisa aphezulu akhiqizwa ngesikhathi sokumba. Lokhu kusiza ukuvimbela ukushisa ngokweqile futhi kunciphisa ingozi yokuguga ngaphambi kwesikhathi noma ukulimala kwe-drill bit.

7. Izinhlayiya zedayimane ezicijile futhi ezisatshalaliswe ngokulinganayo endaweni ye-drill bit ziqinisekisa izimbobo ezibushelelezi nezihlanzekile. Lokhu kubaluleke kakhulu uma ubhoboza ukhonkolo noma itshe, njengoba kusiza ukugcina ubuqotho kanye nobuhle bezinto ezibonakalayo.

8. Nakuba izingcezu ze-vacuum brazed diamond core drill zingase zibe nezindleko eziphakeme zokuqala uma kuqhathaniswa nezinye izinhlobo zama-drill bits, ukusebenza kwazo okuhlala isikhathi eside nokuqina kuzenza zibe utshalomali olungabizi kakhulu ngokuhamba kwesikhathi. Ukuphila kwabo okunwetshiwe kunciphisa isidingo sokushintshwa njalo, okuholela ekongeni ngokuhamba kwesikhathi.

vacuum brazed diamondcore bit imininingwane

| Usayizi | Ububanzi | Ngokuphelele L | Ukusebenza L | Shank L |

| 6mm | 6mm | 64 mm | 30mm | 30mm |

| 8mm | 8mm | 64 mm | 30mm | 30mm |

| 10mm | 10mm | 64 mm | 30mm | 30mm |

| 12mm | 12mm | 64 mm | 30mm | 30mm |

| 14mm | 14mm | 64 mm | 30mm | 30mm |

| 16 mm | 16 mm | 64 mm | 30mm | 30mm |

| 18mm | 18mm | 64 mm | 30mm | 30mm |

| 20mm | 20mm | 64 mm | 30mm | 30mm |

| 22 mm | 22 mm | 64 mm | 30mm | 30mm |

| 25mm | 25mm | 64 mm | 30mm | 30mm |

| 28mm | 28mm | 64 mm | 30mm | 30mm |

| 30mm | 30mm | 64 mm | 30mm | 30mm |

| 32 mm | 32 mm | 64 mm | 30mm | 30mm |

| 35 mm | 35 mm | 64 mm | 30mm | 30mm |

| 40mm | 40mm | 64 mm | 30mm | 30mm |

| 45 mm | 45 mm | 64 mm | 30mm | 30mm |

| 50mm | 50mm | 64 mm | 30mm | 30mm |

| 55 mm | 55 mm | 64 mm | 30mm | 30mm |

| 60mm | 60mm | 64 mm | 30mm | 30mm |